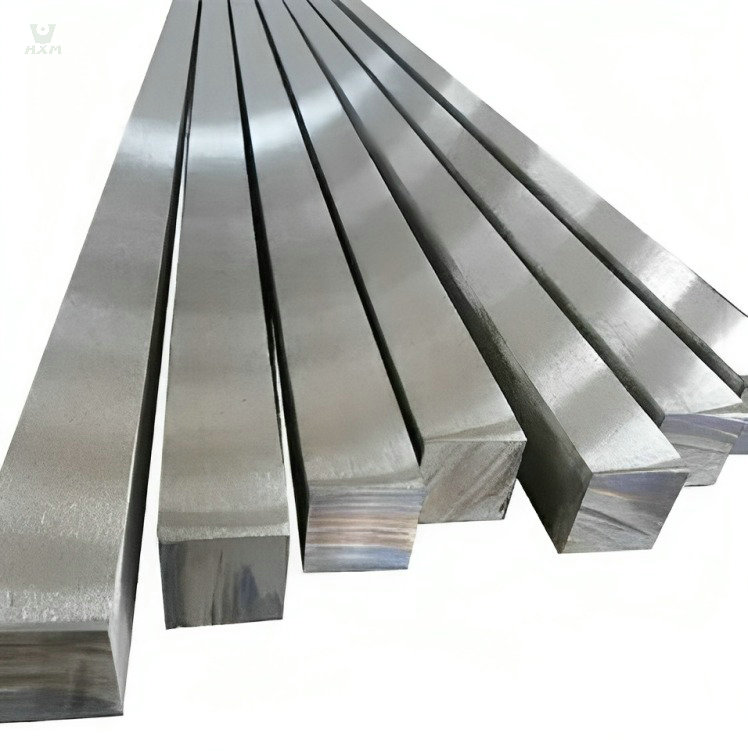

420 Stainless Steel Bar Supplier In China

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Shape: round, flat, square, angle, hexagonal

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 410 Stainless Steel Bar

Renowned for its exceptional strength, corrosion resistance, and outstanding wear resistance, 420 stainless steel is a martensitic stainless steel. Engineered with a unique composition, it combines a relatively high carbon content (0.15 to 0.4%) for hardness and strength with 12% chromium for adequate corrosion resistance. Manganese enhances strength and hardening capability, while silicon aids in deoxidation and strengthens the material. Though it exhibits good corrosion resistance in mild environments, 420 stainless steel is primarily used in applications demanding high strength, moderate corrosion resistance, and good hardness. It finds common use in the manufacturing of cutting tools, surgical instruments, scissors, blades, and a variety of cutting implements. While it provides excellent corrosion resistance in mild conditions, it may not be suitable for highly corrosive or extreme environments, where stainless steels with higher chromium and nickel content, such as 316 or 304 stainless steel, are typically preferred. The production of 420 stainless steel bars involves several steps, beginning with the melting and refining of raw materials, ultimately shaping them into the desired form for manufacturers. Typically supplied in a quenched and tempered state, 420 stainless steel bars offer a hardness range of 700 – 850 MPa (condition R) Brinell hardness range of 201 – 255, or a tensile strength range of 770 – 930 MPa (condition S).

specification Of 410 Stainless Steel Bar

Chemical Composition Of 420 Stainless Steel Bar

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.15 – 0.4 |

| Chromium (Cr) | 12.0 – 14.0 |

| Manganese (Mn) | 1.0 |

| Silicon (Si) | 1.0 |

| Phosphorus (P) | 0.04 |

| Sulfur (S) | 0.03 |

| Iron (Fe) | Balance |

physical property Of 420 Stainless Steel Bar

| Property | Value |

|---|---|

| Density | 7.74 g/cm³ |

| Specific Heat Capacity | 0.50 J/g°C |

| Electrical Resistivity | 550 nΩ·m (at 20°C) |

| Thermal Conductivity | 24.9 W/(m·K) |

| Coefficient of Expansion | 10.3 x 10⁻⁶ /°C |

| Melting Point | 1480°C (2700°F) |

mechanical property Of 420 Stainless Steel Bar

| Property | Value |

|---|---|

| Tensile Strength | 655 – 950 MPa (95,000 – 137,750 psi) |

| Yield Strength (0.2% offset) | 450 MPa (65,250 psi) |

| Elongation at Break | 15% (in 50 mm) |

| Modulus of Elasticity | 190 GPa (27,500 ksi) |

| Poisson’s Ratio | 0.27 |

features Of 410 Stainless Steel Bar

420 Stainless Steel Bar is distinguished by its remarkable hardness and strength, owing to its relatively high carbon content, typically ranging from 0.15% to 0.4%. This elevated carbon content empowers the steel with outstanding structural integrity and resistance to deformation. As a martensitic stainless steel, it undergoes a heat treatment process that further enhances its hardness and strength, making it a preferred choice in applications demanding robust and resilient materials.

The increased carbon concentration not only contributes to the overall hardness but also facilitates improved tensile strength, ensuring that the 420 Stainless Steel Bar can withstand substantial loads and stresses. This combination of exceptional hardness and strength makes it ideal for various applications, particularly in situations where durability and reliability are paramount, such as cutlery, surgical instruments, and industrial cutting tools.

In summary, the hardness and strength of 420 Stainless Steel Bar are a result of its elevated carbon content, making it a dependable material for applications requiring robustness and resistance to wear and deformation.

420 Stainless Steel Bar possesses an essential characteristic, which is its corrosion resistance, primarily attributed to its chromium content. With a chromium content of approximately 12%, this stainless steel variant offers adequate resistance to corrosion in non-aggressive environments. When exposed to mild conditions, such as non-acidic water and wet air, it typically maintains its integrity and withstands the corrosive effects present in such settings.

However, it’s vital to note that the corrosion resistance of 420 Stainless Steel Bar has its limitations. In highly aggressive or extreme conditions, where the environment is laden with corrosive elements or the material is subjected to substantial chemical exposure, its performance may not be as suitable. In such scenarios, stainless steel variants with higher chromium and nickel contents, like 316 or 304 Stainless Steel, are often preferred for their superior corrosion resistance.

In summary, the corrosion resistance of 420 Stainless Steel Bar is attributed to its 12% chromium content, making it a suitable choice for non-aggressive environments, but careful consideration is required when dealing with highly corrosive or extreme conditions.

420 Stainless Steel Bar is highly regarded for its exceptional wear resistance. This attribute is primarily a result of the steel’s composition and microstructure. The presence of a relatively high carbon content within the range of 0.15% to 0.4% contributes significantly to the material’s hardness and wear resistance.

The elevated carbon content in 420 Stainless Steel enhances its ability to withstand abrasive wear and tear. This property makes it particularly well-suited for applications where tools or components are subjected to constant friction, abrasion, or wear. It is often the material of choice for manufacturing cutting tools, surgical instruments, scissors, knife blades, and various cutting implements due to its excellent wear resistance.

However, it’s important to note that while 420 Stainless Steel excels in wear resistance, it may not be the ideal choice for applications requiring the highest level of corrosion resistance, especially in highly corrosive or extreme environments. In such cases, stainless steel alloys with greater corrosion resistance may be preferred.

In summary, the remarkable wear resistance of 420 Stainless Steel Bar is primarily attributed to its elevated carbon content, making it a preferred material for applications where durability in the face of abrasive wear is essential.

420 Stainless Steel Bar exhibits notable strength and hardening capability, owing to its unique composition and microstructure. Key elements in this composition contribute significantly to these properties.

Manganese: The presence of manganese plays a crucial role in enhancing the strength and hardening capability of 420 Stainless Steel. Manganese is a powerful strengthening agent, particularly in solid-solution strengthened alloys like 420. It effectively contributes to the formation of fine-grained structures within the steel during the heat treatment process. These fine grains improve the material’s overall strength and hardening capability.

Silicon: Silicon is another essential element in 420 Stainless Steel. One of its primary functions is deoxidation, which helps remove oxygen and other impurities from the steel during the manufacturing process. This deoxidation process is critical in ensuring the purity and integrity of the material. Additionally, silicon aids in enhancing the steel’s strength.

As a result of these mechanisms, 420 Stainless Steel Bar possesses excellent strength and the ability to harden effectively. This makes it an ideal choice for applications that require materials with high mechanical strength and the capacity to withstand significant loads. Components manufactured from 420 Stainless Steel, such as cutting tools, knife blades, and surgical instruments, benefit from these strength-enhancing properties, ensuring their durability and longevity in demanding usage scenarios.

application Of 410 Stainless Steel Bar

Cutlery Manufacturing

The exceptional hardness and strength of 420 Stainless Steel Bar make it the preferred choice for crafting various types of cutlery. It is widely used in the production of kitchen knives, outdoor blades, and industrial cutting tools, where its robustness and durability are essential for precise cutting and slicing.

Surgical Instruments

Thanks to its outstanding corrosion resistance and hardness, 420 Stainless Steel Bar is a staple in the manufacturing of surgical instruments, including surgical knives and forceps. These instruments demand materials that can maintain sharp edges, resist corrosion, and withstand sterilization processes.

Scissors and Blades

420 Stainless Steel Bar's remarkable hardness and wear resistance qualities also make it an ideal material for crafting scissors and blades. Whether in household or industrial applications, these tools rely on 420 Stainless Steel to retain sharpness and durability, ensuring precise and efficient cutting.

Various Cutting Tools

The hardness and strength of 420 Stainless Steel Bar render it an excellent choice for an array of cutting tools. Woodworking tools, metalworking instruments, and construction tools all benefit from the steel's exceptional properties. Whether it's shaping wood, working with metals, or construction projects, the reliability and longevity of these tools depend on the robustness of 420 Stainless Steel.

In summary, 420 Stainless Steel Bar finds extensive use in applications that demand high strength, moderate corrosion resistance, and superior hardness. While it excels in mild environments, it may not be suitable for highly corrosive or extreme conditions, in which cases stainless steels with higher chromium and nickel content, such as 316 or 304, are often preferred.

FAQ

420 stainless steel bar is primarily composed of iron as the base metal, with specific alloying elements added to impart its unique properties. The key components of 420 stainless steel include:

Iron (Fe): This forms the majority of the material, providing the structural framework and basic properties of steel.

Chromium (Cr): It constitutes around 12-14% of the alloy, contributing to corrosion resistance and enhancing the material’s durability in various environments.

Carbon (C): The carbon content typically falls within the range of 0.15% to 0.4%, which gives 420 stainless steel its hardness and strength.

Manganese (Mn): Manganese content is added to increase strength and hardening capabilities. It usually ranges from 1% to 1.25%.

Silicon (Si): Silicon assists in the deoxidation process and further enhances the material’s strength.

Traces of Impurities (Sulfur and Phosphorus): These elements may exist in minimal amounts as impurities in the steel.

Overall, 420 stainless steel is a martensitic stainless steel alloy designed to provide a combination of hardness, strength, corrosion resistance, and wear resistance. Its composition is tailored to meet specific performance requirements in various industrial applications.

Stainless steel bar supplier offer 420 stainless steel bars, providing customers with a reliable source of this material for their manufacturing needs.

420 stainless steel bar and 430 stainless steel bar are two distinct stainless steel alloys, each with its own unique characteristics. These differences arise primarily from variations in their chemical compositions, making them suitable for specific applications. Here’s how 420 stainless steel differs from 430 stainless steel:

Chemical Composition:

420 Stainless Steel Bar: It contains a relatively high carbon content, typically ranging from 0.15% to 0.4%. This higher carbon content provides 420 stainless steel with greater hardness and strength, making it well-suited for applications requiring these properties. Additionally, it contains around 12-14% chromium, contributing to corrosion resistance.

430 Stainless Steel Bar: In contrast, 430 stainless steel contains less carbon, typically around 0.08% to 0.15%, resulting in lower hardness and strength compared to 420 stainless steel. It has a higher chromium content, usually about 16-18%, which enhances its resistance to corrosion, particularly in mildly corrosive environments.

Applications:

420 Stainless Steel Bar: Due to its higher carbon content and greater hardness, 420 stainless steel is commonly used for applications where hardness and strength are paramount. This includes making cutlery, knives, surgical instruments, and components for various cutting tools.

430 Stainless Steel Bar: 430 stainless steel, with its superior corrosion resistance, finds its applications in environments where avoiding corrosion is crucial but high strength and hardness are not required. This includes applications in kitchen appliances, sinks, and food processing equipment.

420 stainless steel bar supplier offer both 420 and 430 stainless steel bars, ensuring that customers have access to the appropriate material based on their specific needs and the demands of their intended applications. The choice between these two alloys depends on the desired balance of properties for the particular application.

420 stainless steel bar and 304 stainless steel bar are two distinct stainless steel alloys with notable differences. These distinctions arise primarily from variations in their chemical compositions, making them suitable for specific applications. Here’s how 420 stainless steel differs from 304 stainless steel:

Chemical Composition:

420 Stainless Steel Bar: 420 stainless steel contains a relatively high carbon content, typically ranging from 0.15% to 0.4%, which provides excellent hardness and strength. It also contains around 12-14% chromium for corrosion resistance.

304 Stainless Steel Bar: In contrast, 304 stainless steel has a lower carbon content, approximately 0.07% to 0.08%, resulting in lower hardness and strength. It contains about 18-20% chromium, providing good corrosion resistance. It also includes nickel, which enhances its overall corrosion resistance.

Applications:

420 Stainless Steel Bar: Due to its higher carbon content and greater hardness, 420 stainless steel is often used for applications requiring hardness and strength. This includes manufacturing cutlery, knives, surgical instruments, and various cutting tools.

304 Stainless Steel Bar: 304 stainless steel is widely used in applications where corrosion resistance is paramount. It’s commonly used in kitchen appliances, sinks, food processing equipment, and architectural components. Its versatility and resistance to corrosion in various environments make it a popular choice for general-purpose applications.

Stainless steel bar suppliers offer both 420 and 304 stainless steel bars to cater to the diverse needs of customers, ensuring they can select the most suitable material based on the specific requirements of their intended applications. The choice between these two alloys depends on the desired properties needed for the particular application.

420 stainless steel bar is generally considered weldable; however, the welding process requires specific considerations due to its higher carbon content and potential challenges associated with heat-affected zones. Welding should be performed using appropriate techniques and parameters to achieve satisfactory results. It is advisable to consult a stainless steel bar supplier or a qualified welding professional for guidance and best practices when working with 420 stainless steel in welding applications.

recent stainless steel bar products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China