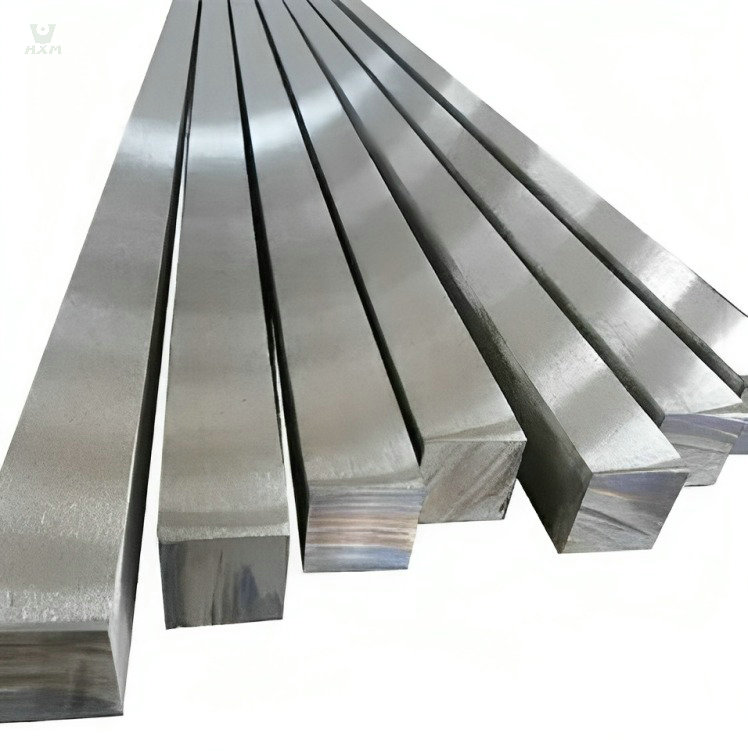

Product Description of Stainless Steel Square Bar

Stainless steel square bars are made of stainless steel ingots, hot rolled or forged.

The production of stainless steel bars has arisen with the development of stainless steel. Due to the wider application range of stainless steel bars, such as the foundation of high-rise buildings in cold areas, the isolation nets next to highways, household goods, etc., the hot rolling production of stainless steel bars has been greatly developed.

Bars account for China’s stainless steel. 30% of products account for only 8%-10% in foreign countries. With the rapid development of cutting-edge technologies such as petroleum, chemical, energy, atomic energy, aerospace, and marine development, higher comprehensive performance requirements for stainless steel are required, which not only requires good corrosion resistance, but also requires high strength, high temperature, and high pressure. The anti-radiation and low-temperature resistance properties have further developed the types of stainless steel.

Production Process of stainless steel square bar

Production Process of Stainless Steel Square Bar

The production process of stainless steel square bars involves several key steps. It begins with melting the raw materials in an electric arc furnace, which can take 8 to 12 hours to achieve a molten state. Subsequently, excess carbon is removed through Argon Oxygen Decarburization (AOD) or, for very low carbon content requirements, Vacuum Oxygen Decarburization (VOD) converters are used. Alloying elements like nickel and molybdenum can be introduced at this stage.

After tuning to fine-tune the chemical composition and ensure consistency, the molten steel is cast into various forms, including blooms, billets, slabs, rods, or tubes. Hot rolling takes place above the recrystallization temperature to form bar and wire from blooms and billets, as well as plate, strip, and sheet from slabs. For precise dimensions or a polished finish, cold rolling is performed at temperatures below the recrystallization point using small-diameter rolls and supporting rolls. This process collectively constitutes the production of stainless steel square bars.

Different Surface Treatment of Stainless Steel Square Bar

The surface of this stainless steel square bar is treated with black oxidation, and the surface appears black, which has certain anti-corrosion properties and aesthetics. This type of stainless steel square bar is usually used to match dark furniture decoration, high-grade indoor escalators, lamps, and hotel decoration and is also an ideal choice.

The surface of this stainless steel square bar has been pickled, showing an off-white, smooth surface, with a certain degree of corrosion resistance and aesthetics. This stainless steel square bar is usually used in the manufacture of kitchen utensils and other fields.

The production process of stainless steel bright bars is similar to that of stainless steel black bars, but the production process requires a polishing process. Usually, polishing machines and grinding heads are used to polish the stainless steel bars to make the surface smoother, brighter, and free of visible oxidation and stains. Its surface treatment technology requires higher precision, so its production cost is relatively high. This stainless steel square bar is commonly used in the manufacture of sanitary ware, watches, jewelry, hardware accessories, medical devices, electronic components, precision machinery, etc.

The production process of stainless steel grinding bars is similar to that of stainless steel bright bars, but it requires grinding treatment. Usually, the grinding machine and grinding head will be used to grind the stainless steel bar so that the surface has a certain grinding effect. Stainless steel grinding bar is usually used for occasions that require a certain abrasive effect on the surface, such as kitchen appliances, door, and window fittings, electronic fittings, etc.

Stainless Steel Bar Common Furnace Type For Melting

Heat treating is an important process in producing alloy steel and chrome steel series products (including stainless steel bars). At present, the domestic steel or bar production line with alloy steel and chromium steel series products heat treatment equipment are roller furnaces (tunnel furnaces), bogie furnaces, hood furnaces, slow cooling pits, etc.

-

Roller Hearth Furnace /Tunnel Furnace

This type of furnace is a continuous heat treatment equipment that can be used for the mass production of bars. The bars are conveyed through the furnace on rollers, and the heating and cooling processes are controlled by the temperature of the furnace atmosphere. This type of furnace is suitable for heat treatment of bars with a diameter of 20 mm-120 mm. -

Trolley Furnace

This type of furnace is a batch-type heat treatment equipment that uses trolleys to transport the bars to be heat-treated. The bars are placed on the trolley and pushed into the furnace. The heating and cooling processes are controlled by the furnace temperature and air circulation. This type of furnace is suitable for heat treatment of bars with a diameter of 10mm-120mm. -

Hood Furnace

This type of furnace is a batch-type heat treatment equipment that uses a hood to cover the bars to be heat-treated. The bars are placed on the tray and pushed into the furnace. The heating and cooling processes are controlled by the furnace temperature and air circulation. This type of furnace is suitable for heat treatment of bars with a diameter of 10mm-50mm. -

Slow Cooling Pit

This type of furnace is a batch-type heat treatment equipment that uses a pit to cool the bars after heat treatment. The bars are placed on a tray and pushed into the pit. The heating and cooling processes are controlled by the furnace temperature and air circulation. This type of furnace is suitable for heat treatment of bars with a diameter of 10mm-50mm.

In summary, the selection of the furnace type depends on the size and quantity of the stainless steel rod to be heat-treated, as well as the specific requirements of the heat-treatment process. The appropriate furnace type can effectively improve the quality and performance of the stainless steel bars.

Common problem while producing stainless steel bar

Because there are no slow cooling and annealing facilities, the rolled bars are directly exposed to the air and cooled, causing the following six major problems:

- Surface crack on the surface of the bar, cleavage defects in the internal structure

- Energy waste, long annealing cycle

- The production logistics organization is not smooth, the products are frequently dumped on the site, the transportation cost is increased, the labor intensity of the post workers is high, and the bar process damages the bar

- Due to any product defects, it is necessary to inspect one by one, the inspection work is heavy and the inspection cost is increased

- Product delivery cycle is long

- Product yield rate is low, customer quality objection

features of Stainless Steel Square Bar

Stainless steel square bars are made up of stainless steels and come in different grades such as 304 and 316. Here are some of the key features of stainless steel square bars:

Durability in stainless steel square bars is underpinned by their unique material properties. Stainless steel’s inherent resistance to heat stems from its ability to withstand high temperatures without deformation or structural degradation. This durability is a result of the alloy’s crystalline structure, which remains stable even under extreme thermal conditions. Low maintenance requirements are due to stainless steel’s natural resistance to corrosion, minimizing the need for protective coatings or constant upkeep. The bars’ impact resistance and flexibility are attributed to the alloy’s molecular structure, which allows it to absorb and distribute energy upon impact without permanent deformation, thus maintaining structural integrity. These scientific principles collectively contribute to stainless steel square bars’ unparalleled durability in various applications.

The corrosion resistance observed in stainless steel square bars is a direct result of their specific alloy composition and the presence of chromium, an essential element within the steel matrix. This resistance is primarily rooted in the formation of a passive oxide layer on the surface of the bars when exposed to oxygen. Chromium interacts with oxygen to create a stable chromium oxide layer that acts as a protective barrier, preventing further oxidation and corrosion. This phenomenon is scientifically known as passivation.

This passive layer is self-repairing, and even when scratched or damaged, it quickly re-forms, maintaining the bars’ resistance to rust and corrosion. The key to this corrosion resistance lies in the scientific principles governing the electrochemical interactions at the molecular level, ultimately resulting in the long-lasting and robust performance of stainless steel square bars.

The remarkable tensile strength of 304 stainless steel square bars is a direct consequence of their unique metallurgical composition and crystalline structure. At the molecular level, stainless steel alloys like 304 consist of iron, chromium, and nickel, among other elements. This combination creates a structure with strong interatomic forces, promoting the material’s tensile strength.

Tensile strength is a measure of the maximum load a material can withstand without breaking or deforming. In stainless steel, this strength is achieved through the organized arrangement of atoms and the bonds between them. Chromium and nickel play a crucial role by promoting both the formation of a stable oxide layer on the surface and enhancing the overall strength of the steel.

This outstanding tensile strength means that 304 stainless steel square bars can withstand substantial loads and stresses, making them ideal for applications where structural integrity and reliability are paramount. This property is a direct result of the complex interplay of atomic forces and material science principles.

The ease of fabrication and maintenance associated with stainless steel square bars is a consequence of their unique material properties and metallurgical characteristics. Stainless steel, especially grades like 304 and 316, boasts excellent formability, ductility, and machinability, which simplify the fabrication process. Here’s a more detailed explanation of this feature:

Formability: Stainless steel square bars can be easily shaped, bent, or cut into a wide range of geometries without experiencing significant cracking or deformation. This formability stems from the steel’s crystal structure, which allows for plastic deformation while maintaining its integrity.

Ductility: Ductility is a crucial property that allows stainless steel to be stretched or drawn into various shapes, making it versatile for different applications. The combination of chromium and nickel in the alloy contributes to this ductile nature.

Machinability: Stainless steel’s machinability is another factor contributing to ease of fabrication. Machinability refers to how easily a material can be cut, drilled, or otherwise shaped during manufacturing. Stainless steel bars, especially those designed for general-purpose applications like 304, offer good machinability.

Low Maintenance: Stainless steel is known for its resistance to corrosion, staining, and rust. As a result, stainless steel square bars require minimal maintenance over their service life. They can withstand harsh environmental conditions without deteriorating, reducing the need for frequent inspections and repairs.

In summary, the ease of fabrication and low maintenance of stainless steel square bars is a product of their intrinsic material characteristics, making them an attractive choice for a wide range of applications.

The environmental friendliness of stainless steel square bars is closely tied to their recyclability and sustainable attributes, driven by the material’s composition and production process. Here’s a detailed explanation of this feature:

Recyclability: Stainless steel, including the square bars made from grades like 304 and 316, is highly recyclable. This recyclability stems from the inherent properties of stainless steel, as it can be melted down and reformed into new products without losing its fundamental characteristics. The recycling process requires less energy compared to the initial production of stainless steel, making it an eco-conscious choice.

Longevity: Stainless steel is renowned for its exceptional durability and resistance to corrosion and wear. These properties contribute to the longevity of stainless steel square bars. When used in various applications, they have a prolonged service life, reducing the need for replacements or disposal.

Resistance to Environmental Degradation: Stainless steel square bars are highly resistant to environmental factors like moisture, acids, and alkalis. This resistance allows them to maintain their structural integrity in harsh conditions without deteriorating, further emphasizing their eco-friendly nature.

Energy Efficiency: The production of stainless steel square bars involves energy-intensive processes, such as melting and rolling. However, stainless steel’s longevity and recyclability translate into long-term energy savings. As these bars can often outlast alternative materials, the need for frequent replacements is reduced, resulting in energy conservation.

In conclusion, the environmental friendliness of stainless steel square bars is a testament to the material’s ability to be reused, its durability, and its resistance to environmental degradation. These attributes contribute to a more sustainable and eco-conscious choice for various applications.

The longevity and strength of stainless steel square bars are inherent characteristics that result from their unique composition and manufacturing processes. Here’s a detailed explanation of this feature:

Material Composition: Stainless steel square bars, such as those made from grade 304 or 316, are alloyed with chromium and nickel, which impart exceptional durability and strength. The addition of these alloying elements provides resistance to corrosion, wear, and environmental factors.

Stress and Load Resistance: Stainless steel square bars exhibit remarkable strength and robustness, allowing them to withstand various forms of stress and heavy loads. This property is crucial in applications where structural integrity is paramount, ensuring that the bars maintain their shape and performance over extended periods.

Corrosion Resistance: The corrosion-resistant nature of stainless steel ensures that these square bars can endure exposure to moisture, chemicals, and other corrosive agents. This resistance contributes to their longevity by preventing degradation over time.

High-Temperature Performance: Stainless steel square bars can maintain their strength and structural integrity at both high and low temperatures. This makes them suitable for a wide range of applications, even in extreme environmental conditions.

Minimal Maintenance: Their resistance to wear and corrosion minimizes the need for frequent maintenance and replacement. This reduces the overall cost of ownership and enhances their service life.

Quality Assurance: The manufacturing processes involved in producing stainless steel square bars are highly controlled, ensuring consistency and quality. This attention to quality contributes to the material’s longevity and strength.

In summary, stainless steel square bars’ longevity and strength are derived from their alloy composition, resistance to corrosion, ability to withstand stress and environmental conditions, and minimal maintenance requirements. These qualities make them a reliable and durable choice for various applications.

application of Stainless Steel Square Bar

Stainless steel square bars are used in a variety of applications due to their strength, corrosion resistance, and versatility. Here are some common applications:

Brewing

In the brewing industry, stainless steel square bars emerge as an indispensable component, meticulously designed to meet the stringent demands of this specialized field. These bars play a pivotal role in reinforcing the vats within breweries, safeguarding the longevity and reliability of brewing equipment. Their exceptional durability and corrosion resistance are paramount in an environment where temperature variations and corrosive substances are commonplace. Stainless steel square bars, often cold-rolled to exacting standards, provide the structural integrity necessary to withstand the rigors of brewing processes. Their precision-crafted properties ensure that the brewing vats maintain their structural integrity, preserving the quality and consistency of the brewing process, which is a cornerstone of the brewing industry's success.

Fencing & Gates

The application of stainless steel square rod in the realm of fencing and gate construction embodies the synergy of strength and aesthetics. These bars, celebrated for their robust properties, play a pivotal role in crafting fencing and gates that not only provide security but also offer an appealing visual presence. Their durability, corrosion resistance, and structural integrity are paramount in ensuring the longevity of fencing structures, particularly in outdoor settings exposed to environmental elements. The stainless steel square bars serve as the backbone of these structures, contributing to their stability and ability to withstand the test of time. Moreover, the sleek and modern aesthetic of stainless steel enhances the overall look, making them a popular choice in architectural and design applications.

Furniture

The utilization of ss square bars in furniture manufacturing represents a harmonious blend of versatility and structural integrity. These bars, revered for their resilience and malleability, play a vital role in crafting furniture components, such as chair and table legs, benches, and stools. Their inherent strength ensures the stability and load-bearing capacity of these items, promising longevity and reliability. Additionally, the ease of welding and bending stainless steel square bars facilitates intricate and customized designs, allowing furniture makers to explore various creative possibilities. Whether it's the sleek legs of a contemporary chair or the robust frame of a rustic bench, stainless steel square bars contribute to the aesthetic appeal and functional excellence of furniture pieces.

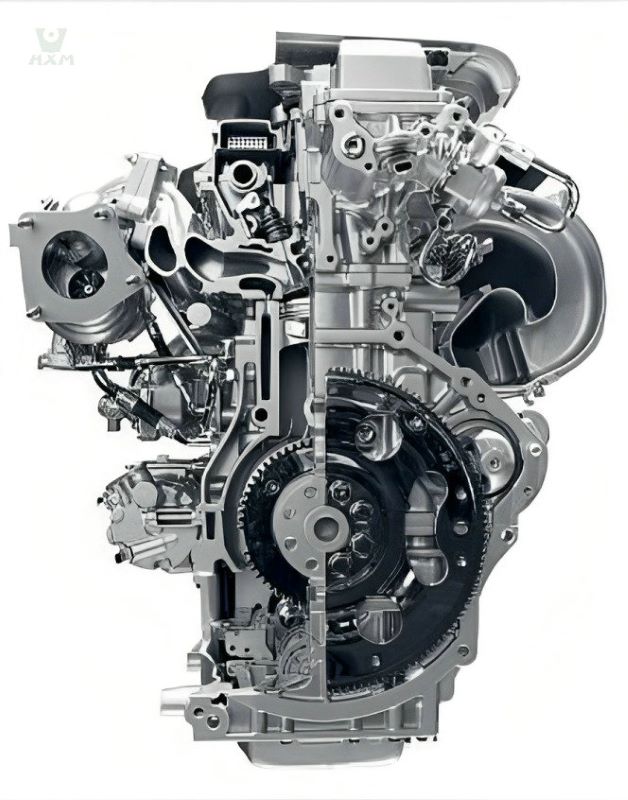

Automobile Industries

The stainless steel square bar's role in the automobile industry is vital and multifaceted, making it an indispensable component in the manufacturing of engine parts for a wide range of vehicles, from cars to buses and trucks. This application demands materials that possess both exceptional strength and versatility. Stainless steel square bars excel in these aspects, ensuring the reliability and endurance of engine components. Their robust nature enables them to withstand the demanding conditions within engines, including exposure to heat and mechanical stress. This, in turn, contributes to the overall performance and safety of the vehicles we rely on daily, highlighting the significance of stainless steel square bars in the automotive sector.

Machining Tools

Stainless steel square bars serve as foundational elements in the manufacturing of machining tools, particularly in the production of metal components like bolts, nuts, and screws. These tools are engineered to endure challenging conditions, including exposure to extreme cold and the necessity to bear heavy loads. The choice of materials is paramount, and stainless steel square bars meet these demands with exceptional strength and versatility. Their inherent durability ensures the longevity and reliability of the machining tools, making them a preferred choice across various industries. Whether it's construction, automotive, or industrial manufacturing, stainless steel square bars contribute significantly to the performance and integrity of essential metal components used worldwide.

FAQ

Yes, stainless steel square bars can be customized to specific dimensions to meet the requirements of your project. Stainless steel bar suppliers offer the flexibility to provide bars in various sizes and shapes, ensuring they align perfectly with your specific needs.

Certainly, stainless steel square bars come in various grades, each tailored to specific applications. Common grades include 304 and 316, recognized for their corrosion resistance and structural integrity. Stainless steel bar suppliers offer a range of grades, ensuring you can choose the one that best suits your project’s requirements. These grades are carefully designed to meet various needs, whether in industries like construction, manufacturing, or food processing, where different levels of corrosion resistance and strength are necessary.

The main distinction between hot-rolled and cold-rolled stainless steel square bars lies in the manufacturing process. Hot-rolled bars are formed at high temperatures, making them more malleable and suitable for applications that don’t require precise dimensions or a smooth surface finish. Cold-rolled bars, on the other hand, undergo the process at lower temperatures, resulting in a more precise size, a smoother surface, and increased strength. Stainless steel bar suppliers offer both options to cater to a wide range of customer needs, ensuring you can select the ideal form for your specific project requirements.

The distinction between hot-rolled and cold-rolled stainless steel square bars primarily relates to the manufacturing process.

Hot-Rolled Stainless Steel Square Bars:

- These bars are formed at high temperatures, typically above the recrystallization point of the steel.

- The high temperature makes the material more malleable, allowing for a wide range of shapes and sizes.

- They are suitable for applications where precise dimensions and surface finish are not critical, such as structural components in construction.

Cold-Rolled Stainless Steel Square Bars:

- Cold rolling occurs at lower temperatures, below the recrystallization point.

- This process yields a smoother surface finish and precise dimensions.

- Cold-rolled bars are often preferred for applications requiring tight tolerances, such as precision machining.

Stainless steel square bar suppliers offer both types to cater to diverse customer needs. The choice between hot-rolled and cold-rolled bars depends on your specific project requirements and the importance of factors like dimensional accuracy, surface finish, and strength.

Stainless steel square bars are generally non-magnetic. Most stainless steel alloys, including the ones used for square bars, belong to the austenitic family, which is characterized by its non-magnetic properties. However, it’s important to note that some cold-worked austenitic stainless steels can become slightly magnetic due to the strain hardening process during manufacturing. In practice, for most applications, stainless steel square bars are considered non-magnetic, making them suitable for various uses where magnetic properties are not desired. Your stainless steel bar supplier can provide more information on the specific magnetic properties of the grade you’re interested in.

Choosing the right grade of stainless steel square bars for your project depends on several factors, including:

Corrosion Resistance: Consider the environmental conditions the bars will be exposed to. If your project is in a corrosive or marine environment, you’ll want a highly corrosion-resistant grade like 316.

Strength Requirements: Different grades offer varying levels of strength. If your project involves heavy loads, opt for a high-strength grade, such as 304 or 316.

Machinability: If you need to machine the bars extensively, look for free-machining grades like 303.

Aesthetic and Surface Finish: Some projects require a specific appearance or surface finish. Grades like 304 often provide an attractive finish.

Temperature Resistance: For applications involving high or low temperatures, choose a grade that offers the necessary thermal resistance.

Your stainless steel bar supplier can assist in selecting the most suitable grade based on your project’s specific requirements.

recent stainless steel bar products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China