The 4 Applications and Benefits of Titanium Alloys

---in the Automotive Industry

News Keywords

- Titanium alloys

- Automotive industry

- Engine components

- Exhaust systems

- Lightweight materials

- Corrosion resistance

- High-temperature applications

- Advanced manufacturing techniques

Introduction to Titanium Alloys

Titanium alloys have become increasingly popular in various industrial applications due to their unique properties. In the automotive industry, titanium alloys offer significant benefits such as high strength-to-weight ratio, excellent corrosion resistance, and the ability to withstand extreme temperatures. This article will explore the specific applications and advantages of titanium alloys in the automotive sector.

Historical Development of Titanium Alloys

The use of titanium alloys in the automotive industry dates back to the late 20th century. In the 1980s, titanium alloys began to be used in high-performance sports cars, and by the 1990s, their application had expanded to mainstream vehicles. Significant milestones include the use of titanium alloys in the 1985 Acura NSX for engine components and the 2000 Chevrolet Corvette Z06 for exhaust systems.

Key Properties of Titanium Alloys

- High Strength and Low Density of Titanium Alloys: Titanium alloys are as strong as steel but 45% lighter, making them ideal for reducing vehicle weight without compromising safety or performance.

- Corrosion Resistance in Titanium Alloys: These alloys are highly resistant to corrosion from environmental factors, enhancing the longevity of automotive components.

- Temperature Resistance of Titanium Alloys: Titanium alloys can withstand extreme temperatures, making them suitable for parts exposed to high heat, such as exhaust systems and engine components.

Applications of Titanium Alloys in the Automotive Industry

- Engine Components Made from Titanium Alloys: Titanium alloys are used in engine valves, connecting rods, and turbocharger wheels due to their ability to withstand high temperatures and reduce rotational inertia, improving engine performance and fuel efficiency.

- Titanium Alloys in Exhaust Systems: The use of titanium alloys in exhaust systems reduces weight and enhances corrosion resistance, leading to better performance and longer lifespan.

- Suspension Systems Utilizing Titanium Alloys: Titanium alloys springs and suspension components offer a balance of strength and weight reduction, improving vehicle handling and comfort.

- Structural Components of Titanium Alloys: In electric vehicles (EVs), titanium alloys are used to reinforce battery enclosures and other structural parts, enhancing safety without adding significant weight.

Advances in Titanium Alloys Processing

Recent advancements in processing technologies have made titanium alloys more cost-effective and accessible for automotive applications. Techniques such as powder metallurgy and additive manufacturing (3D printing) allow for the precise production of complex titanium alloys components, reducing material waste and production costs.

Future Prospects for Titanium Alloys

The future of titanium alloys in the automotive industry looks promising. As manufacturers continue to seek lightweight, durable materials to improve fuel efficiency and performance, the use of titanium alloys is expected to grow. Innovations in alloy composition and processing methods will further enhance the properties and reduce the costs of titanium alloys components.

Conclusion on Titanium Alloys

Titanium alloys offer numerous benefits for the automotive industry, including reduced weight, increased strength, and excellent resistance to corrosion and high temperatures. These advantages make titanium alloys an ideal material for various automotive applications, from engine components to structural parts. As processing technologies advance, the use of titanium alloys is likely to expand, driving further innovations and improvements in vehicle performance and efficiency.

By understanding and leveraging the properties of titanium alloys, the automotive industry can continue to develop safer, more efficient, and higher-performing vehicles.

Contact us today to learn more about how our high-quality titanium alloys can meet your specific needs and drive your automotive projects forward. Let us help you harness the power of titanium alloys for superior performance and innovation.

Duplex Steel 2205 Coils: Understanding the Applications and Uses

Duplex Steel 2205 Coils: Understanding the Applications and Uses Duplex Steel 2205 Coils Duplex Steel 2205 coils are widely used duplex stainless steel alloy known

What Are Steel Coils Used For ?

What are steel coils used for? stainless steel coils supplier in China Steel has been at the core of industrial development for centuries, and steel coils play

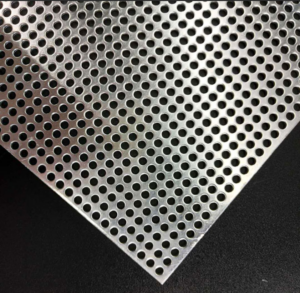

Top 10 Applications of Perforated Metal in Architectural Projects

Top 10 Applications of Perforated Metal in Architectural Projects perforated metal (stainless steel sheet) Perforated metal has long been a staple in industrial design, but

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications stainless steel pipe What is Stainless steel pipe rolling? Stainless steel pipe rolling is a

How Are Stainless Steel Welded Tubes Made?

How Are Stainless Steel Welded Tubes Made? stainless steel welded tubes Stainless steel welded tubes are a vital component in various industries, including construction, automotive,

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446 Each stainless steel sheet has its own unique