When Was Stainless Steel Invented?

Today, we use stainless steel products almost every day, from kitchen appliances to construction and transportation equipment. But did you know when stainless steel was invented? What was the world like when stainless steel was invented? Did people back then realize that they were creating revolutionary material that would play an important role in the world of tomorrow? These seemingly simple questions involve a lot of historical and technological background.

When was stainless steel invented?

Stainless steel was invented in 1913 by Harry Brearley, a British scientist. At the time, he was looking for a material that would resist corrosion in order to solve a problem that had arisen in British manufacturing at the time. He added chromium to iron to create a new alloy that is known today as stainless steel. This invention revolutionized the modern stainless steel factories and provided people with a strong, corrosion-resistant material.

In this article, we will delve into the historical background of the invention of stainless steel and its impact on modern society, exploring how it has become one of the most common materials in the modern world.

PART ONE

Background of the invention of stainless steel

PART TWO

The invention of stainless steel on the impact of the industry at the time

PART THREE

The difference between stainless steel and traditional steel

PART FOUR

The prospects for stainless steel in the future

Background of the invention of stainless steel

The background of the invention of stainless steel can be traced back to the industrial revolution in the early 19th century. At that time, with the rapid development of industries, factories, and the acceleration of urbanization, the demand for steel materials in factories has grown. However, traditional steel materials have a serious problem and are vulnerable to environmental corrosion. This problem was especially prominent in the marine, chemical, and food industries.

Therefore, scientists began to study how to create a new type of steel material with anti-corrosion properties. The following scientists made a great contribution to the process of the invention of stainless steel:

- The first scientist to try to develop stainless steel is the British chemist, Perkins, he found a synthetic method that can be used for dyes in the early 19th century, in which the synthetic agent used is the chromate commonly used in stainless steel.

- After that, the German scientist August W. von Hofmann 1861 found that chromium has corrosion resistance, which inspired later scientists to explore the corrosion resistance of chromium-containing alloys.

- Later, the German scientist Albert von Osten 1912 successfully developed stainless steel containing chromium, which is one of the important milestones in the history of the invention of stainless steel.

In this context, the British scientist Harry Brearley also threw himself into the invention of stainless steel. Brearley conducted numerous experiments in the laboratory, trying to add a variety of different alloying elements to explore new materials. His initial goal was to study how to improve the barrel of a firearm to make it more durable and corrosion-resistant. However, as his research progressed, he began to turn his attention to the steel material itself, trying to find a new and better steel material.

After continuous testing, Brearley found that when the chromium content exceeded 10.5%, the steel would be able to resist corrosion. Finally, he found a way to add chromium to steel, and in 1913, the invention of stainless steel successfully appeared, which is the modern sense of stainless steel. This invention of stainless steel caused a sensation at the time and not only ushered in the era of stainless steel but also established Brearley’s reputation as a scientist. His invention of stainless steel has become an integral part of the industry, profoundly affecting people’s production and life.

The invention of stainless steel is a scientific and technological breakthrough, which uses the chemical properties of chromium to successfully prevent the erosion of steel by corrosive substances such as oxygen, water, and acid. This invention of stainless steel makes it the properties that ordinary steel does not have, greatly expanding the scope of application of steel materials, and promoting the development of modern stainless steel factories.

In short, the invention of stainless steel is a major achievement in the history of human industry, its application range continues to expand, and the construction and development of modern society have played a vital role.

The invention of stainless steel in 1913 had a great impact on the stainless steel factories of that time. In that era, the rapid development of stainless steel factories brought higher productivity and more opportunities, but the problem of corrosion of steel materials had been troubling people. The invention of stainless steel solved this problem and brought significant improvements to the industrial sector.

In the first few years after the invention of stainless steel, Factories began to use stainless steel to make durable, corrosion-resistant machinery and tools, greatly improving production efficiency and product quality. For example, in chemical, paper, pharmaceutical, food, and other industries, the invention of stainless steel has been widely used because of its excellent anti-corrosion properties, becoming a new material to replace traditional ferrous materials. In addition, because of its good toughness and strength, stainless steel has also been used in the manufacture of aircraft, automobiles, ships, and other transportation parts. In the factories of medical equipment, tableware, watches, and other daily necessities manufacturing, stainless steel also began to gradually replace traditional metal materials. Overall, although the scope of application of stainless steel at the time was relatively limited, its excellent performance in the industrial factories and a wide range of application prospects, prompted people to further research and promote it.

The invention of stainless steel allowed factories to produce more durable and reliable materials and products more efficiently, thus bringing more convenience and economic benefits to society at the time. At the same time, the invention of stainless steel also provided new ideas and directions for research in materials science and related factories, opening up new areas for the advancement of science and technology.

After Harry Brearley invented stainless steel, people began to research and develop other alloy materials with special properties, such as high-temperature alloys, high-strength alloys, etc. The invention and application of these new materials have promoted the development of aerospace, military, nuclear industry, and other factories. In addition, the anti-corrosion properties of stainless steel have also inspired people to study the corrosion resistance of materials, thus promoting the research and application of anti-corrosion materials. Therefore, the invention of stainless steel has provided new ideas and directions for materials science and related fields, promoting the progress of materials science and technology.

The difference between stainless steel and traditional steel

The main difference between stainless steel and traditional steel is the addition of alloying elements. Traditional steel contains a high percentage of carbon, which is prone to rust and corrosion. The invention of stainless steel, on the other hand, has added alloy elements such as chromium, nickel, and molybdenum, which are capable of forming a dense oxide film that protects the surface of the steel from corrosion. Stainless steel factories have also adopted modern equipment and technology to produce high-quality stainless steel products. These advantages have allowed stainless steel to replace traditional steel in many areas

Specifically, chromium is one of the most important alloying elements in the invention of stainless steel, which can react with oxygen to form a dense chromium oxide film that prevents further corrosion of the steel surface. In addition, stainless steel can be modified chemically and physically by the addition of other elements. For example, elements such as cobalt, nickel, molybdenum, and copper can improve the strength and wear resistance of stainless steel. Elements such as titanium and niobium can improve the corrosion resistance of stainless steel. Therefore, different types of stainless steel have different properties and uses.

The difference between stainless steel and traditional steel in terms of performance

The difference between stainless steel and traditional steel in terms of anti-corrosion performance is mainly reflected in the following aspects:

Alloying Elements: Stainless steel contains a high proportion of chromium and other alloying elements (such as nickel, molybdenum, etc.), these alloying elements can form a dense oxide film layer, thus effectively preventing further erosion of the metal surface by oxygen, water and other chemicals.

Ferrite and Austenite: The different proportions of ferrite and austenite in stainless steel result in a different crystal structure than that of ordinary steel. This crystal structure makes stainless steel have better corrosion resistance.

Surface Treatment: Stainless steel surface after polishing and other treatments can form a smoother surface, the surface is more difficult to be corroded.

Application Areas: Stainless steel is widely used in areas that require corrosion resistance, such as pharmaceutical, food processing, chemical industry, etc., while traditional steel is mainly used in construction, machinery manufacturing and other fields.

There are also some differences between stainless steel and conventional steel in terms of strength and hardness. Compared to ordinary steel, stainless steel has higher strength and hardness. This is due to the addition of a variety of alloying elements in stainless steel, such as chromium, nickel, molybdenum, etc. The addition of these alloying elements can improve the strength and hardness of stainless steel, and does not reduce its corrosion resistance. In addition, stainless steel also has higher ductility and toughness, which means it can better withstand stress and deformation without breaking or fracturing.

In contrast, conventional steel may be less strong and harder, but also has better machinability and malleability. Conventional steel is also relatively inexpensive to manufacture because it requires fewer alloying elements and the production process is relatively simple. However, conventional steel has poor corrosion resistance and is susceptible to oxidation and corrosion, making it unusable in some special environments.

Stainless steel and traditional steel also differ in terms of coefficient of thermal expansion. The coefficient of thermal expansion is the rate of change of physical quantities such as length, area and volume when an object changes in temperature. Because stainless steel contains elements such as chromium and nickel, its coefficient of thermal expansion is relatively low, so the shape and dimensions of stainless steel change less when the temperature changes. In contrast, conventional steel has a relatively high coefficient of thermal expansion and therefore has a large change in shape and size when the temperature is changed.

This property makes stainless steel more suitable for use in high or low temperature environments, such as in the chemical, aerospace, and nuclear industries. In these application scenarios, there are large changes in temperature, and the low coefficient of thermal expansion of stainless steel can reduce the shape and dimensional changes caused by temperature changes, thus improving the stability and reliability of equipment and components.

Stainless steel and conventional steel also differ in terms of welding performance. Because of the many alloying elements added to stainless steel, its melting point is higher than that of ordinary steel, and its thermal conductivity is lower, so it requires higher welding temperature and longer welding time. At the same time, stainless steel is prone to oxidation during welding, so it needs to use some special welding methods and equipment, such as inert gas shielded welding, to avoid defects such as oxidation and cracking at the weld. In addition, the heat-affected zone (Heat-Affected Zone, HAZ) of stainless steel is more prone to brittle fracture than ordinary steel, so it is necessary to control the welding temperature and welding speed when welding to avoid the problem of brittle fracture.

The difference between stainless steel and traditional steel in terms of sanitary performance is mainly manifested in the following aspects:

Stainless steel surface is smooth, burr-free, easy to clean and disinfect, will not breed bacteria and viruses. While the traditional steel surface may have burrs, bumps, it is difficult to achieve a thorough cleaning effect.

Stainless steel is added with chromium and other elements, can form a dense oxide protective film, with a certain degree of corrosion resistance, can be in different environments for a long time to maintain a smooth, flat surface. The traditional steel lack of this oxide protective film, easy to rust, corrosion, affecting hygiene.

Stainless steel has a high corrosion resistance, can withstand a variety of strong acids, strong alkalis and other corrosive media, will not produce secondary pollution. And traditional steel in contact with strong acids, strong alkalis and other corrosive media are prone to corrosion, secondary pollution.

In summary, stainless steel has obvious advantages in sanitary performance, widely used in pharmaceutical, food, medical equipment and other fields, to become one of the important materials to protect public health.

the prospects for stainless steel in the future

With the continuous development of technology and the expansion of applications, the invention of stainless steel has a very broad prospect. The demand for stainless steel in factories, construction, transportation, energy, and other fields will continue to grow, which will prompt stainless steel factories to adopt more advanced production techniques and equipment to improve production efficiency and quality and reduce costs. The following are the prospects for the development of stainless steel in the future:

The continuous expansion of application areas

With the continuous development of the global economy, the application areas of stainless steel are also expanding. Stainless steel has been widely used in construction, automotive, electronics, chemical, medical, food processing and many other fields, and will involve more in the future.

Research and development of new stainless steel

Scientists are constantly researching and developing new stainless steel to meet the needs of different applications. These new stainless steels have better performance and a wider range of applications, bringing new opportunities for the development of the stainless steel industry.

Increased environmental awareness

As people’s awareness of environmental protection increases, stainless steel as a recyclable material will receive more attention and application. In the future, the stainless steel factories will pay more attention to environmental protection and strengthen recycling and reuse.

3D printing technology

With the continuous development of 3D printing technology, the 3D printing technology of stainless steel is also progressing. In the future, the 3D printing technology of stainless steel factories will be able to manufacture more precise and complex structures, bringing new changes to the development of manufacturing.

Conclusion

In the history of human development, stainless steel is undoubtedly a revolutionary material. Its appearance has greatly changed people’s understanding of steel and has also contributed to the rapid development of modern industry. Stainless steel not only has excellent performance but is also widely used in various fields, such as construction, aviation, energy, medicine, etc. At the same time, the invention of stainless steel has also created a new situation in materials science and related fields, opening up new areas for the progress of science and technology. Stainless steel factories will play an increasingly important role in the future, promoting the continued development and innovation of the stainless steel industry. It can be expected that in future development, stainless steel will continue to play an important role and make greater contributions to the progress and development of mankind.

Duplex Steel 2205 Coils: Understanding the Applications and Uses

Duplex Steel 2205 Coils: Understanding the Applications and Uses Duplex Steel 2205 Coils Duplex Steel 2205 coils are widely used duplex stainless steel alloy known

What Are Steel Coils Used For ?

What are steel coils used for? stainless steel coils supplier in China Steel has been at the core of industrial development for centuries, and steel coils play

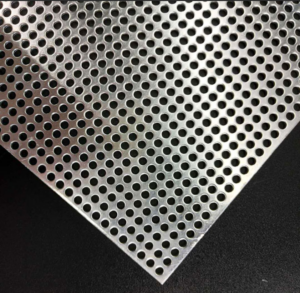

Top 10 Applications of Perforated Metal in Architectural Projects

Top 10 Applications of Perforated Metal in Architectural Projects perforated metal (stainless steel sheet) Perforated metal has long been a staple in industrial design, but

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications stainless steel pipe What is Stainless steel pipe rolling? Stainless steel pipe rolling is a

How Are Stainless Steel Welded Tubes Made?

How Are Stainless Steel Welded Tubes Made? stainless steel welded tubes Stainless steel welded tubes are a vital component in various industries, including construction, automotive,

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446 Each stainless steel sheet has its own unique