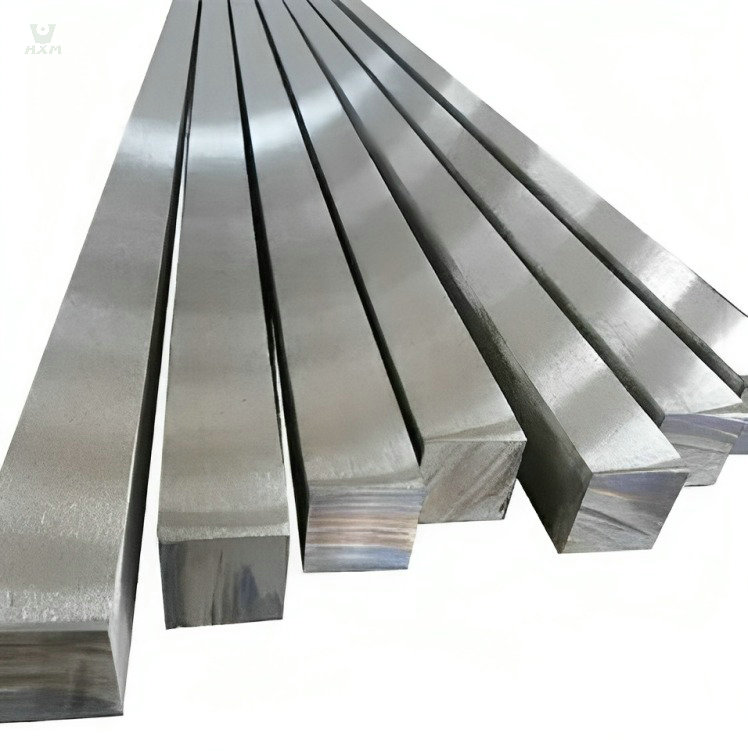

316L Stainless Steel Bar Supplier

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Main Grade: 201, 304, 316, 316L, 310s, 430

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 316L Stainless Steel Bar

The 316L stainless steel bar stands as a testament to durability and corrosion resistance, making it an indispensable material in a wide array of applications. Crafted from an austenitic chromium-nickel alloy, this stainless steel marvel boasts an exceptional composition, characterized by elevated levels of nickel and molybdenum. These elements collectively bestow upon it an unparalleled resistance to corrosion, far surpassing that of its 304 stainless steel counterpart.

What truly sets the 316L stainless steel bar apart is its remarkable resilience in the face of corrosive environments laden with chloride. It not only resists corrosion but also tackles pitting and crevice corrosion with remarkable fortitude. This resilience is especially vital in applications where exposure to chemical corrodents is commonplace. Industries such as chemical processing, textiles, paper and pulp, and heat exchangers have found a trusted ally in the 316L stainless steel bar, thanks to its unwavering performance in the harshest of settings.

The 316L stainless steel bar is not merely robust; it is also exceptionally versatile. Its malleability allows for convenient welding, while its ductility and formability ensure that it can be seamlessly molded into various shapes and structures. Despite its impressive strength, this stainless steel grade retains its magnetism-free nature, in line with its austenitic lineage. Heat treatment may not harden it, but its enduring qualities make it a reliable choice in elevated-temperature scenarios.

Delving deeper into its mechanical prowess, the 316L stainless steel bar excels in situations requiring elevated strength, particularly at higher temperatures. It boasts superior creep resistance, stress-to-rupture ratios, and tensile strength. This combination of attributes makes it the material of choice when durability, corrosion resistance, and strength are non-negotiable.

Moreover, the ‘L’ in 316L stands for a lower carbon content, strategically designed to enhance corrosion protection during welding. This thoughtful engineering further underscores its suitability for demanding applications.

specification Of 316L Stainless Steel Bar

chemical composition of 316L Stainless Steel Bar

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.030 |

| Silicon (Si) | ≤ 0.75 |

| Manganese (Mn) | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

physical property of 316L Stainless Steel Bar

| Property | Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Point | 1399 – 1454°C (2550 – 2650°F) |

| Thermal Conductivity | 14.6 W/m·K (10.1 BTU·in/hr·ft²·°F) at 100°C (212°F) |

| Specific Heat Capacity | 502 J/kg·K (0.12 BTU/lb·°F) at 20°C (68°F) |

| Electrical Resistivity | 74.0 µΩ·m (in ohm·circ mil/ft) |

| Magnetic Properties | Non-Magnetic |

mechanical property of 316L Stainless Steel Bar

| Property | Value |

|---|---|

| Tensile Strength | 485 – 620 MPa (70.3 – 89.9 ksi) |

| Yield Strength (0.2% offset) | ≥ 170 MPa (≥ 24.7 ksi) |

| Elongation at Break | ≥ 40% |

| Modulus of Elasticity | 193 GPa (28.0 x 10^6 psi) |

| Hardness (Brinell) | ≤ 217 HB |

characteristics Of 316L Stainless Steel Bar

The exceptional corrosion resistance of 316L Stainless Steel Bar can be attributed to its unique composition. With a high nickel and molybdenum content, this stainless steel grade forms a protective chromium oxide layer on its surface when exposed to corrosive environments. This passive oxide layer acts as a barrier, preventing further interaction between the metal and corrosive agents.

This remarkable characteristic provides several advantages for 316L Stainless Steel Bar. Firstly, it ensures the longevity of the material, even in aggressive settings such as marine or chemical processing environments. Secondly, it minimizes the risk of pitting and crevice corrosion, common challenges in chloride-rich conditions. This resistance to corrosion makes 316L Stainless Steel Bar highly reliable and durable, making it an ideal choice for critical applications where structural integrity and longevity are essential.

The weldability of 316L Stainless Steel Bar is a notable characteristic resulting from its austenitic microstructure. This stainless steel grade exhibits excellent weldability due to its low carbon content, which reduces the risk of carbide precipitation and sensitization during welding. The ability to form strong and durable welds makes it highly suitable for various fabrication processes and applications.

During welding, 316L Stainless Steel Bar can be easily fused with other stainless steel components or materials, offering versatility in construction and design. Its weldability ensures secure and robust connections, contributing to the structural integrity of assemblies and equipment. This feature makes 316L Stainless Steel Bar a preferred choice in industries where reliable and resilient welding is crucial, such as in the construction of chemical processing equipment, pipelines, and architectural structures.

The ductility and formability of 316L Stainless Steel Bar are remarkable attributes derived from its austenitic microstructure. This stainless steel grade exhibits exceptional malleability and elongation properties, making it highly ductile and formable. Its molecular structure allows for easy deformation and shaping without compromising its mechanical integrity.

The ductility of 316L Stainless Steel Bar enables it to be readily drawn, bent, or manipulated into various intricate shapes and configurations, making it a preferred choice in applications requiring complex designs or custom components. Its formability ensures ease of fabrication, allowing manufacturers to achieve precise specifications and intricate detailing. This feature is particularly advantageous in industries such as architecture, where the material’s ability to conform to intricate architectural designs enhances both aesthetic appeal and functionality.

The non-magnetic nature of 316L Stainless Steel Bar stems from its unique austenitic structure. Unlike ferromagnetic materials, such as regular carbon steels, 316L stainless steel does not exhibit magnetic properties. This characteristic is a result of its atomic arrangement, where the magnetic moments within its crystal lattice cancel each other out.

The non-magnetic property of 316L Stainless Steel Bar is advantageous in various applications, especially those requiring compatibility with magnetic-sensitive equipment or environments. This feature prevents interference with sensitive electronic devices, magnetic resonance imaging (MRI) machines, and other precision instruments. Additionally, the absence of magnetic properties simplifies handling and installation processes, as magnetic attraction is not a concern. Overall, the non-magnetic nature of 316L stainless steel contributes to its versatility and suitability in diverse industrial and scientific settings.

The high-temperature strength of 316L Stainless Steel Bar can be attributed to its unique composition and crystal structure. Its alloy contains a significant amount of nickel and molybdenum, which enhance its performance at elevated temperatures.

At high temperatures, 316L stainless steel exhibits excellent creep resistance, meaning it can withstand prolonged exposure to stress without significant deformation. Its stress-to-rupture and tensile strength properties remain robust under these conditions, making it a reliable choice for applications in demanding thermal environments.

This exceptional high-temperature strength allows 316L stainless steel to maintain its structural integrity and mechanical properties even when subjected to extreme heat. Consequently, it finds extensive use in industries where elevated temperatures and challenging operating conditions are prevalent, such as chemical processing, power generation, and aerospace applications. Its ability to withstand these conditions ensures the durability and reliability of components made from 316L stainless steel, contributing to its widespread adoption in various critical applications.

The low carbon content in 316L Stainless Steel Bar is a deliberate and essential feature that contributes significantly to its exceptional corrosion resistance and weldability. By reducing the carbon content to a minimum, typically around 0.03%, the formation of chromium carbide precipitates is effectively minimized during welding and exposure to high-temperature environments.

This reduction in carbide formation is crucial because it helps preserve the integrity of the stainless steel’s corrosion-resistant passivity. In simpler terms, it prevents the depletion of chromium near the grain boundaries, maintaining the material’s resistance to corrosive attacks.

Additionally, the low carbon content enables 316L stainless steel to be more easily weldable without the risk of sensitization—a condition where the material becomes susceptible to intergranular corrosion. This makes it an ideal choice for applications where welding is required, ensuring that the welded joints remain corrosion-resistant and durable.

In summary, the low carbon content in 316L stainless steel is a key factor in enhancing its corrosion resistance and weldability, making it a preferred material for various industries, including chemical processing, marine environments, and medical devices, where both durability and corrosion resistance are paramount.

application Of 316L Stainless Steel Bar

Food Preparation Equipment

316L stainless steel bars find extensive use in the food industry, particularly in food handling, cooking, and storage equipment. Its attributes, including durability, ease of cleaning, resistance to bacterial growth, and non-reactivity with food, make it a preferred choice for various culinary applications.

Medical Industry

With its excellent biocompatibility, 316L stainless steel bars are highly suitable for medical applications. They are commonly used in the production of surgical instruments and medical implants, where biocompatibility and corrosion resistance are critical.

Construction Industry

In the construction sector, stainless steel 316L round bars serve multiple purposes. They are employed as reinforcement bars, enhancing the structural integrity of concrete elements. Additionally, these bars are used as anchor screws, ensuring robust connections in construction projects. Moreover, their aesthetic appeal makes them a choice material for architectural applications such as railings and handrails, where both strength and visual appeal are essential.

FAQ

316L and 304 stainless steel bars are both widely used in various industries, but they have some key differences:

Chemical Composition:

- 316L Stainless Steel: It contains higher amounts of molybdenum and nickel compared to 304 stainless steel, which enhances its corrosion resistance. This makes 316L more suitable for marine and chloride-rich environments.

- 304 Stainless Steel: It has a lower nickel content, making it less corrosion-resistant in certain environments but more cost-effective.

Corrosion Resistance:

- 316L Stainless Steel: Exceptional resistance to corrosion, especially in chloride environments like coastal areas and chemical processing.

- 304 Stainless Steel: Good corrosion resistance but not as effective as 316L in chloride-rich conditions.

Applications:

- 316L Stainless Steel: Commonly used in marine environments, chemical processing equipment, and medical devices due to its superior corrosion resistance.

- 304 Stainless Steel: Used in a wide range of applications, including food processing, kitchen equipment, and architectural components.

Weldability:

- 316L Stainless Steel: It is readily weldable with standard processes, maintaining its corrosion resistance after welding.

- 304 Stainless Steel: Also weldable but may require post-weld annealing to prevent corrosion in certain applications.

Strength:

- 316L Stainless Steel: Generally has slightly lower tensile strength than 304 stainless steel.

Magnetic Properties:

- 316L Stainless Steel: Like 304 stainless steel, it is non-magnetic in its annealed state.

In summary, 316L stainless steel offers superior corrosion resistance, making it ideal for harsh environments, while 304 stainless steel is more cost-effective and suitable for many general-purpose applications. The choice between them depends on the specific requirements of the application and the level of corrosion resistance needed. A reputable stainless steel bar supplier can provide guidance based on your project’s needs.

Maintaining and cleaning 316L stainless steel bars is essential to preserve their appearance and performance. Here are scientific steps to ensure proper care:

Regular Cleaning:

- Clean the bars regularly with warm water and a mild detergent or a solution of water and vinegar. This helps remove dirt, grime, and fingerprints.

Avoid Abrasive Materials:

- Never use abrasive materials like steel wool, harsh scrubbing pads, or abrasive cleaners, as they can scratch the surface and compromise the stainless steel’s corrosion resistance.

Direction of Cleaning:

- Always clean in the direction of the grain (the brushed finish on the steel). This minimizes the visibility of potential scratches.

Rinse Thoroughly:

- After cleaning, rinse the bars with clean water to remove any residue from the cleaning agents.

Dry Completely:

- Ensure the bars are thoroughly dried after cleaning to prevent water spots or streaks.

Stainless Steel Cleaner:

- For stubborn stains or discoloration, you can use a stainless steel cleaner specifically designed for this purpose. Follow the manufacturer’s instructions.

Passivation:

- Periodic passivation may be necessary to restore the protective oxide layer on the stainless steel’s surface. Consult with your stainless steel bar supplier for guidance on passivation methods.

Avoid Chlorides:

- Avoid exposure to chlorides, such as bleach or pool chemicals, as they can cause pitting and corrosion. If contact occurs, rinse promptly with clean water.

Protective Coatings:

- Consider applying a protective coating, like a clear lacquer or wax, to further shield the bars from environmental factors and fingerprints.

Consult a Supplier:

- If you encounter specific issues or have unique cleaning requirements, consult your stainless steel bar supplier for expert advice.

Proper maintenance and cleaning practices will help ensure the longevity and aesthetic appeal of your 316L stainless steel bars, making them suitable for a wide range of applications, including marine environments, medical devices, and architectural components.

Yes, you can weld 316L stainless steel bars. In fact, 316L stainless steel is known for its excellent weldability. Its low carbon content (the “L” in 316L) reduces the risk of carbide precipitation and subsequent corrosion around the weld area, making it suitable for welding applications. Common welding methods for 316L stainless steel include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and shielded metal arc welding (SMAW).

To ensure a successful weld, consider the following scientific guidelines:

Clean Surface: Ensure that the surfaces to be welded are clean and free from contaminants, such as oil, grease, or dirt.

Proper Filler Material: Select the appropriate filler material compatible with 316L stainless steel. Consult your stainless steel bar supplier for recommendations.

Controlled Heat: Maintain precise control over the welding heat to prevent overheating, which can lead to distortion and reduced corrosion resistance.

Back Purging: In critical applications, consider using back purging with inert gas to protect the weld’s backside from oxidation.

Post-Weld Passivation: After welding, passivate the welded area to restore the stainless steel’s protective oxide layer.

Expertise: If you are not experienced in welding stainless steel, it’s advisable to seek the expertise of a qualified welder or consulting your stainless steel bar supplier for guidance.

Welding 316L stainless steel bars can be done effectively when following proper techniques, ensuring strong and corrosion-resistant joints for various applications, including construction, industrial equipment, and more.

The price range for 316L stainless steel bars can vary depending on several factors, including the specific dimensions, quantities, and market conditions. Generally, you can expect the cost of 316L stainless steel bars to be influenced by factors like:

Market Demand: Fluctuations in demand for stainless steel products, influenced by various industries, can impact pricing.

Size and Dimensions: Larger or custom-sized bars may be priced differently from standard sizes.

Quantity: Bulk purchases may come with cost advantages compared to smaller quantities.

Quality and Grade: Premium quality and certified 316L stainless steel bars may be priced higher.

Finish: The desired finish (e.g., polished, brushed) can affect the price.

Supplier: Different suppliers may offer competitive pricing based on their manufacturing and distribution capabilities.

To get an accurate price range, it’s recommended to contact stainless steel bar suppliers directly. They can provide you with up-to-date pricing based on your specific requirements and prevailing market conditions.

316L stainless steel bar and 316 stainless steel bar are closely related grades, but there are some key differences that set them apart:

Carbon Content: The ‘L’ in 316L stands for “low carbon.” It has a lower carbon content compared to 316 stainless steel. This lower carbon content in 316L provides improved corrosion resistance, especially in welding applications. It reduces the risk of sensitization and carbide precipitation, which can lead to corrosion.

Weldability: Due to its lower carbon content, 316L is often preferred in welding applications. It is less likely to develop sensitization and is more resistant to intergranular corrosion after welding.

Corrosion Resistance: Both grades offer excellent corrosion resistance, but 316L stainless steel’s lower carbon content provides slightly better resistance in chloride environments, such as marine or coastal applications.

Applications: 316L is commonly used in applications where welding is required and where the avoidance of corrosion is critical. It is widely used in the chemical, pharmaceutical, and medical industries, as well as in marine equipment.

While 316 and 316L stainless steel bars share many similarities, the lower carbon content of 316L makes it the preferred choice for applications where welding and corrosion resistance are primary concerns. For specific application requirements, consulting with a stainless steel bar supplier is advisable to determine the most suitable grade.

Selecting the right 316L stainless steel bars for your project involves considering several factors:

Application: Determine the specific application and environment where the bars will be used. Consider factors such as exposure to corrosive substances, high temperatures, or mechanical stress.

Grade: Confirm that 316L stainless steel is the appropriate grade for your project. If welding is required, 316L is often preferred due to its low carbon content.

Size and Shape: Choose the appropriate size, diameter, and shape of bars based on your project’s design and structural requirements.

Finish: Decide on the desired surface finish, whether it’s polished, ground, or another finish that meets your project’s aesthetic and functional needs.

Certifications: Ensure that the stainless steel bars meet relevant industry standards and certifications for your application.

Supplier: Select a reputable stainless steel bar supplier with a track record of providing high-quality materials. Check for supplier certifications and customer reviews.

Budget: Consider your budget constraints and find stainless steel bars that offer the right balance of quality and cost-effectiveness for your project.

Consultation: If you’re uncertain about the best choice for your project, consult with a stainless steel bar supplier or a materials engineer who can provide expert guidance based on your specific requirements.

By carefully assessing these factors and working with a knowledgeable supplier, you can confidently choose the right 316L stainless steel bars for your project, ensuring long-lasting performance and reliability.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China