Stainless Steel Channel Bar Supplier

Size: 5# – 40#, 40 x 20 – 200 x 100

Standard: GB1220, ASTM A 484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Main Grade: 201, 304, 316, 316L, 310s, 430

Finish: Black, NO.1, mill finish, cold draw

product description of stainless steel channel bar

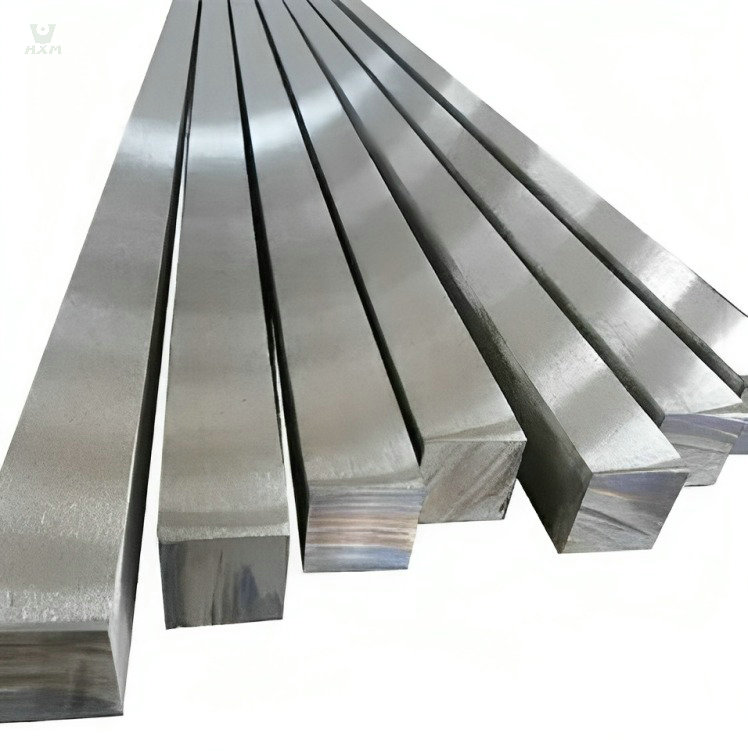

The Stainless Steel Channel Bar, also known as the C Channel, is a highly versatile and essential structural component, renowned for its exceptional strength and superior resistance to corrosion. Crafted through the hot rolling process, this product features a distinctive channel shape with rounded inside radius corners, making it an ideal choice for a wide spectrum of structural applications that demand both robustness and longevity.

One of the notable attributes of the stainless steel channel bar is its flexibility to accommodate varying requirements. Its dimensions, including height and width, can be tailored to suit specific project needs, offering a tailored solution for diverse applications. Importantly, the flanges and webs of this channel bar maintain consistent material thickness, ensuring cost-effectiveness without compromising structural integrity.

Moreover, the stainless steel channel bar is indispensable in the manufacturing sector, contributing to the production of robust equipment and machinery. Its exceptional strength and durability ensure that it can withstand the demands of heavy-duty industrial applications, making it a cornerstone for engineering projects.

In terms of material options, the channel bar predominantly utilizes austenitic grades such as 304, 304L, 316, and 316L, which are celebrated for their corrosion-resistant properties. However, customization is readily available to cater to specific material grade requirements upon request.

specification of stainless steel channel bar

Main grade description in different standard

ASTM | DIN / EN | JIS | GB | ISO Name | Other |

S20100 201 | 1.4372 | SUS201 | S35350 | X12CrMnNiN17–7-5 | J1 L1 LH 201J1 |

S20200 202 | 1.4373 | SUS202 | S35450 | X12CrMnNiN18–9-5 | 202 L4, 202 J4, 202 J3 |

S30400 304 | 1.4301 | SUS304 | S30408 | X5CrNi18-10 | 06Cr19Ni10 0Cr18Ni9 |

S31603 316L | 1.4404 | SUS316L | S31603 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 00Cr17Ni14Mo2 |

S40900 409 | – | SUH409 | S11168 | X5CrTi12 | 0Cr11Ti |

S40910 409L | 1.4512 | SUH409L | S11163 | X2CrTi12 | 00Cr11Ti 022Cr11Ti |

S41008 410S | 1.4000 | SUS410S | S11306 | X6Cr13 | – |

S43000 430 | 1.4016 | SUS430 | 10Cr17 | X6Cr17 | 1Cr17 |

Main grade chemical components in different standard

201 | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Mo % |

ASTM | 0.15 | 1.00 | 5.5-7.5 | 0.050 | 0.030 | 3.5-5.5 | 16.0-18.0 | 0.25 | – |

DIN/EN | 0,15 | 1,00 | 5,5-7,5 | 0,045 | 0,015 | 3,5-5,5 | 16,0-18,0 | 0,05-0,25 | – |

JIS | 0.15 | 1.00 | 5.5-7.5 | 0.060 | 0.030 | 3.5-5.5 | 16.0-18.0 | 0.25 | – |

GB | 0.15 | 1.00 | 5.5-7.5 | 0.050 | 0.030 | 3.5-5.5 | 16.0-18.0 | 0.05-0.25 | – |

202 | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Mo % |

ASTM | 0.15 | 1.00 | 7.5-10.0 | 0.060 | 0.030 | 4.0-6.0 | 17.0-19.0 | 0.25 | – |

DIN/EN | 0,15 | 1,00 | 7,5-10,5 | 0,045 | 0,015 | 4,0-6,0 | 17,0-19,0 | 0,05-0,25 | – |

JIS | 0.15 | 1.00 | 7.5-10.0 | 0.060 | 0.030 | 4.0-6.0 | 17.0-19.0 | 0.25 | – |

GB | 0.15 | 1.00 | 7.5-10.0 | 0.050 | 0.030 | 4.0-6.0 | 17.0-19.0 | 0.05-0.25 | – |

304 | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Mo % |

ASTM | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 8.0 – 10.5 | 18.0-20.0 | 0.10 | – |

DIN/EN | 0,07 | 1,00 | 2,00 | 0,045 | 0,015 | 8,0 – 10,5 | 17,5-19,5 | 0,10 | – |

JIS | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0 – 10.5 | 18.0-20.0 | – | – |

GB | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0 – 10.0 | 18.0-20. 0 | – | – |

316L | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Mo % |

ASTM | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 10.0-14.0 | 16.0-18.0 | 0.10 | 2.00-3.00 |

DIN/EN | 0,030 | 1,00 | 2,00 | 0,045 | 0,015 | 10,0-13,0 | 16,5-18,5 | 0,10 | 2,00-2,50 |

JIS | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 12.0-15.0 | 16.0-18.0 | – | 2.00-3.00 |

GB | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 10.0-14.0 | 16.0-18.0 | 0.10 | 2.00-3.00 |

409 | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Ti % |

ASTM | 0.08 | 1.00 | 1.00 | 0.045 | 0.03 | 0.50 | 10.5-11.7 | – | 6*C% – 0.75 |

DIN/EN | – | – | – | – | – | – | – | – | – |

JIS | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | – | 10.5-11.7 | – | 6*C% – 0.75 |

GB | 0.08 | 1.00 | 1.00 | 0.045 | 0.030 | 0.60 | 10.5-11.7 | – | 6*C% – 0.75 |

409L | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Ti % |

ASTM | 0.03 | 1.00 | 1.00 | 0.040 | 0.020 | 0.50 | 10.5-11.7 | 0.03 | 6*(C+N)-0.5 |

DIN/EN | 0.03 | 1.00 | 1.00 | 0.040 | 0.015 | – | 10.5-12.5 | – | 6*(C+N)-0.65 |

JIS | 0.03 | 1.00 | 1.00 | 0.040 | 0.030 | – | 10.5-11.7 | – | 6*C% – 0.75 |

GB | 0.03 | 1.00 | 1.00 | 0.040 | 0.020 | – | 10.5-11.7 | 0.03 | Ti≥8*(C+N) |

410S | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Mo % |

ASTM | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 0.60 | 11.5-13.5 | – | – |

DIN/EN | 0,08 | 1,00 | 1,00 | 0,040 | 0,015 | – | 12,0-14,0 | – | – |

JIS | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | – | 11.5-13.5 | – | – |

GB | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 0.60 | 11.5-13.5 | – | – |

Main grade mechanical property in different standard

201 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 260 | 515 | 40 | – | 95 | 217 | – |

JIS | 275 | 520 | 40 | 241 | 100 | – | 253 |

GB | 205 | 515 | 30 | - | 99 | – | - |

202 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 260 | 620 | 40 | – | – | 241 | – |

JIS | 275 | 520 | 40 | – | 95 | 207 | 218 |

GB | – | – | – | – | – | – | – |

304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 92 | 201 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 515 | 40 | – | 92 | 201 | 210 |

316L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 485 | 40 | – | 95 | 217 | – |

JIS | 175 | 480 | 40 | 187 | 90 | 200 | |

GB | 170 | 485 | 40 | – | 95 | 217 | 220 |

409 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | – | – | – | – | – | – | – |

JIS | 175 | 360 | 22 | 162 | 80 | – | 175 |

GB | – | – | – | – | – | – | – |

409L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 380 | 20 | – | 88 | 179 | – |

JIS | 175 | 360 | 25 | 162 | 80 | – | 175 |

GB | 170 | 380 | 20 | – | 88 | 179 | 200 |

410S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 415 | 22 | – | 89 | 183 | – |

JIS | 205 | 410 | 20 | – | 88 | 183 | 200 |

GB | 205 | 415 | 20 | – | 89 | 183 | 200 |

Production Process and Feature of stainless steel channel bar

Heating method

Austenitic stainless steel is stable when heated and cannot be strengthened by quenching. This type of steel has good strength and toughness, excellent low-temperature toughness, no magnetism, and good processing, forming, and welding properties, but it is easy to produce work hardening. At the same time, this type of steel has a very low thermal conductivity and is very ductile at low temperatures, so the heating rate can be faster than that of ferritic stainless steel, slightly lower than the heating rate of plain carbon steel.

Roll hole design

When producing stainless steel bars, the roll hole type generally adopts an elliptical-round hole type system. When designing the hole type, it is considered that the hole type has strong adaptability, and the replacement hole type and the rolling mill restart are minimized, that is, the hole type can be adapted to a variety of products, allowing the hole type to have a larger gap adjustment, so that the entire product range to minimize the hole shape change of the pre-finishing mill.

Rolling temperature control

When stainless steel is rolled, its deformation resistance is quite sensitive to temperature changes. Especially in rough rolling, due to the low rolling speed, the temperature rise caused by deformation work is not enough to compensate for the temperature drop of the rolling stock itself, resulting in a large head-to-tail temperature difference. Product tolerances have an adverse effect and surface defects and internal defects can also occur on the rolled stock, affecting the uniformity of the final product performance.

In order to solve the above problems, the heated billet is subjected to rough rolling, and then enters a fuel (or gas) holding furnace or an induction reheating furnace which is disposed between the rough rolling and the intermediate rolling, and the temperature is uniformized before entering the medium rolling unit. Rolling. In order to control the excessive temperature rise of the rolled parts during the finish rolling and pre-finishing, a water-cooling device (water tank) is generally provided between the two sets of rolling mills and between the finishing mill stands. Therefore, reasonable control of the grain size can be achieved in order to improve the technical performance of the final product.

Online heat treatment of stainless steel

In the past, the heat treatment of stainless steel bars was carried out offline. With the development of science and the deepening of rolling process research, modern stainless steel heat treatment is also carried out online. When producing bar, for austenitic and ferritic stainless steel, it is not easy to produce cold cracking and self-pointing, air cooling or stack cooling after rolling, or water cooling device before flying shear to achieve residual heat quenching; production In the case of martensitic stainless steel, it is easy to produce cold cracking, and cannot be directly cooled into the cooling bed by water cooling. The structure of the cooling bed is different from the cold bed for producing carbon steel. One method is to adopt an improved stepped rack.

cold bed

A cold bed, such as the cold bed of the US Teledyne AIIvac plant, which was designed by Danieli in Italy in 1989, protrudes into a tank on the high-temperature side. The tank can be filled with water to submerge the cold bed in the water so that the austenitic stainless steel can be carried out. Water quenching, but not water quenching, directly enters the cooling bed. The cooling bed can also be equipped with a heat-insulating hood to delay the cooling of the rolling stock. When the insulating cover is used for delayed cooling, the cooling rate is half of the natural cooling rate. The lower cooling rate is very important to ensure the hysteresis brittle crack of the martensitic stainless steel; the other method is: to design one half of the cooling bed into a chain type, and the other half is a common rack type cooling bed.

The roller conveyor is provided with a heat preservation cover. When the martensite stainless steel is produced, the flying shears cut the rolled piece into a double ruler or a fixed length. If it is a multiple rulers, the chain-type cold bed is quickly pulled into the heat preservation cover, and cut into a cover in the cover. The ruler is then sent to the thermal insulation pit, and the fixed ruler is directly pulled into the thermal insulation pit for slow cooling.

features of stainless steel channel bar

The feature of “Durability” in stainless steel channel bars refers to their exceptional ability to withstand the test of time and maintain their structural integrity even in demanding conditions. This durability is primarily attributed to the inherent properties of stainless steel.

Stainless steel channel bars are highly resistant to corrosion, which is a key factor contributing to their longevity. They can endure exposure to moisture, chemicals, and various environmental factors without succumbing to rust or deterioration. This corrosion resistance ensures that they remain in excellent condition over extended periods, reducing the need for frequent replacements or maintenance.

Furthermore, stainless steel channel bars are designed to withstand physical stresses and loads without deforming or weakening. Their robust construction and structural stability make them suitable for applications where strength and longevity are paramount.

In summary, the “Durability” of stainless steel channel bars reflects their remarkable ability to resist corrosion, endure challenging environments, and maintain structural integrity, ensuring they can serve their intended purpose effectively for an extended lifespan. This durability is a key reason why stainless steel channel bars are favored in a wide range of structural and industrial applications.

“Corrosion Resistance” is a fundamental characteristic of stainless steel channel bars, highlighting their exceptional ability to withstand chemical reactions and environmental factors that cause corrosion and deterioration in many other materials. Here’s a detailed explanation of this crucial attribute:

Stainless steel channel bars exhibit outstanding corrosion resistance due to their unique composition, primarily composed of iron, chromium, and nickel. Chromium, in particular, plays a vital role in forming a passive oxide layer on the surface of the steel. This oxide layer, known as chromium oxide (Cr2O3), acts as a protective barrier against corrosive elements, such as moisture, oxygen, and chemicals.

The key aspects of corrosion resistance in stainless steel channel bars include:

Passive Oxide Layer: The passive oxide layer created by chromium prevents the underlying steel from direct contact with corrosive agents, effectively shielding it from degradation.

Chemical Resistance: Stainless steel channel bars can withstand exposure to a wide range of chemicals, including acids, alkalis, and organic solvents, without suffering corrosion or material breakdown.

Moisture and Humidity Resistance: They are highly resistant to the effects of moisture and humidity, making them suitable for applications in wet or damp environments, including outdoor structures.

Saltwater Resistance: Stainless steel channel bars excel in resisting the corrosive effects of saltwater, making them indispensable in marine and coastal construction.

Long-Term Durability: This corrosion resistance ensures the longevity of stainless steel channel bars, as they can maintain their structural integrity even in aggressive industrial or marine settings.

Low Maintenance: The need for maintenance is significantly reduced due to their resistance to corrosion. This translates to cost savings and longer service life.

Versatility: Their ability to resist corrosion makes stainless steel channel bars versatile for use in various industries, including construction, architecture, chemical processing, and marine engineering.

In summary, the corrosion resistance of stainless steel channel bars is a vital attribute that ensures their reliability and longevity in diverse applications. This resistance to corrosion allows them to maintain their appearance and structural strength, even when exposed to challenging conditions, contributing to their widespread use across different industries.

The cost-effectiveness of stainless steel channel bars is a notable feature that underscores their economic advantages and long-term value. Here’s a detailed explanation of this characteristic:

Long Service Life: Stainless steel channel bars are renowned for their exceptional durability and resistance to corrosion, ensuring a significantly longer service life compared to many other materials. This extended lifespan minimizes the need for frequent replacements, reducing overall maintenance and replacement costs.

Reduced Maintenance Expenses: Due to their resistance to corrosion and wear, stainless steel channel bars require minimal maintenance. This translates to lower maintenance expenses, as they do not need protective coatings or constant repairs to maintain their integrity.

Minimal Downtime: In industrial and structural applications, downtime for maintenance or replacement can be costly. Stainless steel channel bars’ durability and reliability minimize downtime, leading to increased productivity and cost savings.

Recyclability: Stainless steel is highly recyclable, and its scrap value contributes to its cost-effectiveness. At the end of its service life, stainless steel channel bars can be recycled, further reducing the environmental impact and providing potential revenue.

Resale Value: Stainless steel channel bars maintain their structural and aesthetic qualities over time, making them attractive for resale in the used materials market. This can offset initial procurement costs.

Versatility: Stainless steel channel bars are versatile and suitable for a wide range of applications, eliminating the need for different materials for various projects. This versatility reduces procurement and inventory costs.

High Strength-to-Weight Ratio: Stainless steel’s high strength-to-weight ratio allows for the use of lighter sections while maintaining structural integrity. This not only saves on material costs but also reduces transportation and installation expenses.

Resistant to Price Fluctuations: Unlike some materials subject to volatile price fluctuations, stainless steel channel bars have relatively stable pricing, providing cost predictability for projects.

In summary, the cost-effectiveness of stainless steel channel bars stems from their longevity, low maintenance requirements, recyclability, and versatile applications. They offer a compelling economic proposition by reducing both initial and long-term costs, making them a preferred choice for various structural and industrial projects.

The high-temperature resilience of stainless steel channel bars is a crucial feature that sets them apart. Here’s a detailed explanation of this characteristic:

Exceptional Heat Resistance: Stainless steel channel bars exhibit remarkable heat resistance, allowing them to maintain their structural integrity and mechanical properties even at elevated temperatures. This property makes them suitable for applications subjected to high-temperature environments, such as industrial furnaces, exhaust systems, and heat exchangers.

Oxidation Resistance: Stainless steel’s alloy composition, including chromium, forms a protective oxide layer on the surface when exposed to high temperatures. This oxide layer acts as a barrier, preventing further oxidation and maintaining the material’s strength and corrosion resistance.

Low Thermal Expansion: Stainless steel has a relatively low coefficient of thermal expansion, meaning it expands or contracts less when exposed to temperature fluctuations. This characteristic reduces the risk of warping or distortion in high-temperature applications, ensuring dimensional stability.

Creep Resistance: Creep is the gradual deformation of a material under constant load at high temperatures. Stainless steel channel bars, especially those containing nickel and other alloying elements, exhibit excellent resistance to creep, making them suitable for long-term use in high-temperature environments.

Thermal Cycling Durability: Stainless steel’s ability to withstand repeated thermal cycling between high and low temperatures without degradation is crucial in applications like heat exchangers and automotive exhaust systems.

Retained Strength: Stainless steel maintains its mechanical strength at elevated temperatures, ensuring that structural components remain robust and reliable in challenging environments.

Resistance to Scaling: Stainless steel resists scaling, a process where metal surfaces deteriorate due to exposure to high temperatures and oxidative conditions. This resistance contributes to the material’s durability in high-temperature applications.

Fire Resistance: Stainless steel’s high-temperature resilience makes it an excellent choice for structures and equipment that require fire resistance, such as building supports and safety barriers.

In conclusion, the high-temperature resilience of stainless steel channel bars makes them suitable for a wide range of applications in demanding environments where exposure to elevated temperatures is a constant factor. Their ability to withstand heat, resist oxidation, and maintain strength ensures their long-term performance and safety, making them a valuable material choice.

Versatility in sizing and forming is a notable characteristic of stainless steel channel bars. Here’s a detailed explanation of this feature:

Customizable Dimensions: Stainless steel channel bars are available in a wide range of dimensions, allowing for customization to meet specific project requirements. These dimensions include height, width, and thickness, providing flexibility for various structural applications.

Various Profile Shapes: Stainless steel channels come in different profile shapes, including C channels, U channels, and J channels. This variety of shapes enhances their versatility, making them suitable for diverse structural and architectural designs.

Hot-Rolled and Laser Fused: Stainless steel channel bars are typically hot-rolled for sizes below 60 x 120 x 7 mm. However, for larger or non-standard dimensions, laser-fused or press bending methods are employed. This adaptability in the forming process ensures that stainless steel channels can be tailored to fit specific project needs.

Ease of Machining: Stainless steel’s machinability allows for additional modifications and shaping as required. This feature is particularly useful in industries that demand precision, such as manufacturing equipment and machinery components.

Bending and Welding: Stainless steel channel bars can be bent and welded to create complex structures. The material’s inherent strength and ductility make it suitable for these processes, enabling innovative designs in construction and architecture.

Drilling and Fastening: Stainless steel channels can be easily drilled and fastened together or to other materials, facilitating secure and robust connections in structural applications.

Surface Finish Options: Stainless steel channels offer various surface finish options, including mill finish, sandblast finish, brushed finish, and polished finish. This versatility in surface treatment allows for aesthetic customization while maintaining the material’s corrosion resistance.

Compatibility with Other Materials: Stainless steel channel bars can be integrated with other materials, such as glass, wood, or concrete, in architectural and construction projects, providing design flexibility and enhancing structural integrity.

In summary, the versatility in sizing and forming of stainless steel channel bars makes them adaptable to a wide range of applications. Their ability to be customized, combined with different profile shapes and forming methods, allows engineers, architects, and builders to create innovative and functional structures while benefiting from the inherent strengths of stainless steel, including corrosion resistance and durability.

Application of stainless steel channel bar

supports, brackets, and frames

Stainless steel channel bars are widely used in construction for supports, brackets, and frames. For example, they provide essential structural support in building construction, where they are used as beams, columns, and framework elements, ensuring the integrity and stability of the structure. In industrial settings, stainless steel channel bars serve as sturdy brackets for heavy machinery, securely holding equipment in place. Moreover, in the automotive industry, these channel bars find application as robust frames and chassis components, enhancing vehicle durability and safety. Their corrosion resistance and high strength make them indispensable in various architectural and engineering applications.

maritime applications

Stainless steel channel bars play a vital role in maritime applications due to their exceptional corrosion resistance. They are commonly used in the construction of boat and ship components such as handrails, guardrails, and structural supports. These channel bars endure the harsh conditions of saltwater exposure, ensuring the safety and durability of marine vessels. Additionally, they are utilized in the manufacturing of marine platforms, docks, and offshore structures, where their resistance to corrosion from seawater and environmental factors is crucial. Their reliability in maritime environments contributes to the longevity and performance of various marine structures and equipment.

food processing equipment

Stainless steel channel bars find extensive use in food processing equipment due to their hygienic properties and resistance to corrosion. They are widely employed in the fabrication of conveyor systems, food handling machinery, and equipment frames within food processing plants. These channel bars provide structural support, ensuring the integrity and stability of food processing lines. Additionally, they are used in the construction of sanitary surfaces, such as countertops and workstations, where cleanliness is paramount. Their corrosion resistance and ease of cleaning make them ideal for maintaining strict hygiene standards in the food industry, contributing to the safe and efficient processing of food products.

FAQ

Yes, there are different grades of stainless steel channel bars available, catering to various applications and requirements. Stainless steel bar suppliers offer a range of grades, including 304, 316, 316L, 304L, and more. These grades differ in their chemical compositions, corrosion resistance, and mechanical properties, allowing customers to choose the most suitable grade for their specific needs. The choice of grade depends on factors like the environment, temperature, and load-bearing requirements of the application. It’s essential to consult with a reputable stainless steel bar supplier to select the appropriate grade for your project.

Choosing the right size and thickness of a stainless steel channel bar for your project depends on several factors, including the load it needs to support, the span it needs to cover, and the environmental conditions it will be exposed to. To make an informed decision, consider consulting with a stainless steel bar supplier who can provide expert guidance based on your specific project requirements. They can help you select the appropriate dimensions and grade of stainless steel channel bar to ensure it meets the structural and corrosion resistance needs of your application.

Yes, Huaxiao stainless steel bar supplier typically offers customization options for stainless steel channel bars. You can often request specific sizes, dimensions, and finishes to meet the unique requirements of your project. This flexibility allows you to tailor the channel bars to your precise needs, ensuring they are a perfect fit for your application.

Yes, Huaxiao stainless steel channel bars are known for their low maintenance requirements. Stainless steel’s inherent corrosion resistance and durability mean that channel bars made from this material typically require minimal upkeep. Routine cleaning to remove surface contaminants and dirt is usually sufficient to keep them in excellent condition. However, specific maintenance practices may vary depending on the environmental conditions and the intended application, so it’s advisable to consult with Huaxiao stainless steel bar supplier for guidance on maintenance best practices tailored to your project.

Huaxiao stainless steel channel bars are manufactured through a precise and controlled process. Here are the general steps involved in their production:

Raw Material Selection: High-quality stainless steel raw materials are carefully selected, including the type and grade of stainless steel that meets the desired specifications.

Melting: The chosen stainless steel raw materials are melted in an electric or induction furnace. The intense heat ensures the materials become molten and are ready for the next steps.

Casting: Once the stainless steel is molten, it is cast into the desired shape for channel bars. The casting process allows for the initial formation of the bars.

Hot Rolling: After casting, the bars are hot-rolled to further refine their shape and dimensions. This process enhances the mechanical properties of the channel bars.

Cooling: The hot-rolled channel bars are then cooled to stabilize their structure.

Cold Drawing: In some cases, cold drawing may be employed to further refine the dimensions and improve the surface finish of the channel bars.

Finishing: The channel bars undergo various finishing processes, such as annealing, straightening, polishing, and cutting, to meet specific requirements.

Quality Control: Throughout the manufacturing process, quality control measures are in place to ensure that the channel bars meet the desired specifications and standards.

Huaxiao stainless steel bar supplier follows stringent quality control practices to deliver high-quality stainless steel channel bars tailored to your project’s needs.

Yes, Huaxiao stainless steel channel bars can be welded using appropriate welding techniques. Stainless steel channel bars are known for their weldability, and they can be joined together or to other components using various welding methods, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and stick welding.

It’s important to ensure that the welding process is performed by skilled professionals with experience in welding stainless steel. Proper welding procedures, filler materials, and post-weld treatments should be used to maintain the corrosion resistance and mechanical properties of the stainless steel channel bars.

Huaxiao stainless steel bar supplier can provide guidance on the welding processes and materials suitable for your specific project requirements.

Yes, Huaxiao stainless steel channel bars are typically manufactured to comply with various industry standards and certifications. These standards ensure the quality and performance of the stainless steel products. Common standards and certifications for stainless steel channel bars include:

ASTM (American Society for Testing and Materials): ASTM standards provide specifications for various grades and dimensions of stainless steel channel bars.

ANSI (American National Standards Institute): ANSI standards may also apply to stainless steel channel bars, depending on the intended use and industry requirements.

ISO (International Organization for Standardization): ISO certifications may be available for stainless steel products, indicating that they meet international quality and safety standards.

Mill Test Certificates (MTCs): Huaxiao stainless steel bar supplier typically provides Mill Test Certificates, which certify the chemical composition, mechanical properties, and other relevant information of the stainless steel channel bars.

These certifications and standards compliance ensure that the stainless steel channel bars meet the necessary quality and performance criteria for specific applications and industries. Customers can request documentation to verify compliance with these standards when purchasing stainless steel channel bars from Huaxiao.

The price range of stainless steel channel bars can vary widely depending on several factors, including the grade of stainless steel, the size and thickness of the channel bar, the finish, and the quantity ordered. Huaxiao stainless steel bar supplier offers competitive pricing tailored to the specific requirements of each customer. To get an accurate price quote for stainless steel channel bars, it is recommended to contact Huaxiao directly, providing details such as the desired grade, dimensions, quantity, and any specific finish or customization requirements for a personalized quotation.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China