Do you have any questions about our products or are you looking for a professional 409&409L stainless steel sheets supplier?

409&409L Stainless Steel Sheet and Plate Suppliers

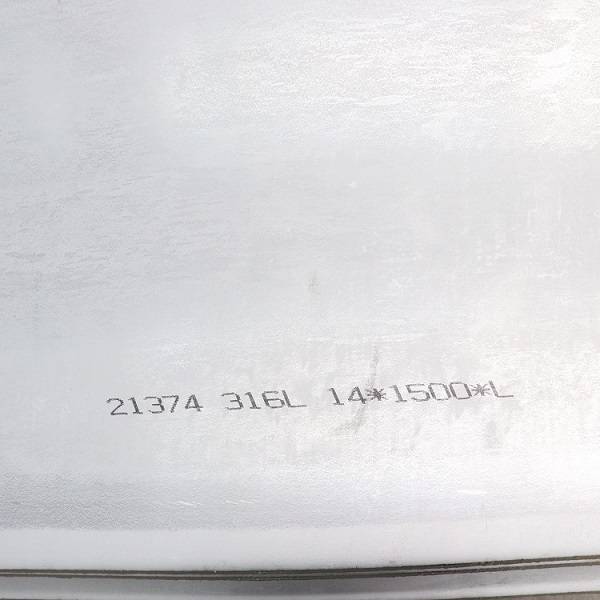

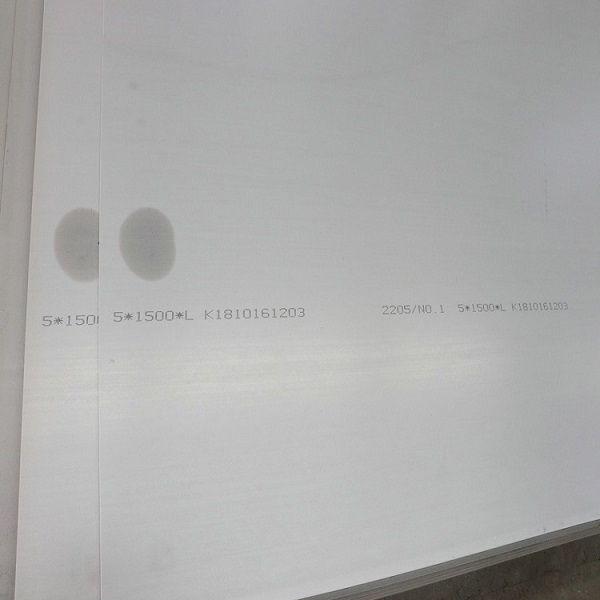

Specifications: Alloy 409 (UNS S40900), S40910, EN 1.4512, SS 409, JIS SUS 409, BS STS409, ASTM A268M, S40910, S40920 S40930, ASTM A240M

Features: moderate corrosion resistance, good formability, and excellent high-temperature oxidation resistance.

Thickness: 0.05mm – 200mm; Width: 300mm – 2000mm; Length: 500mm-12000mm

Finish: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand

blast, Brush, etching, etcCertification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, L/C

Price: Inquiry Grade 409/409L Stainless Steel Sheets Lastest Price Now!

Production Range of 409 stainless steel sheet and plate

-Cold Rolled 409 409LStainless Steel Sheet and Plate, Cold rolled 409 409L sheets, Cold rolled 409 409L Plate

- Thickness: 0.05mm – 3.0mm

- Width: 300mm – 2000mm, the narrowed products pls check in strip products

- Length: 1000mm-6000mm

- Finish: 2B, 2D

-Hot Rolled 409 409L Stainless Steel Sheet and Plate, Hot Rolled 409 409L Sheet, Hot Rolled 409 409L Plate,409 409L PMP, 409 409L CMP

- Thickness: 1.2mm – 200mm

- Width: 300mm – 3200mm

- Length: 500mm – 12000mm

- Finish: Black, NO.1, Anneal pickling

409&409L Grade Description in Different Standard

409&409L Grade Description in Different Standard

Grade | ISO Name | ASTM | DIN / EN | JIS | GB | Other |

409 | X5CrTi12 | S40900 / 409 | – | SUH409 | S11168 | 0Cr11Ti |

409L | X2CrTi12 | S40910 / 409L | 1.4512 | SUH409L | S11163 | 00Cr11Ti / 022Cr11Ti |

Ingredients of 409&409L Stainless Steel Sheets&Plates

| 409 | C % | Si % | Mn % | P% | S% | Cr% | Ni% |

| ASTM | ≤ 0.08 | ≤ 1.0 | ≤ 1.0 | ≤ 0.045 | ≤ 0.03 | 10.5-11.75 | ≤ 0.50 |

| JIS | ≤ 0.08 | ≤ 1.0 | ≤ 1.0 | ≤ 0.045 | ≤ 0.03 | 10.5-11.70 | ≤ 0.50 |

| EN | ≤ 0.08 | ≤ 1.0 | ≤ 1.0 | ≤ 0.045 | ≤ 0.03 | 10.5-12.50 | ≤ 0.50 |

| GB | ≤ 0.08 | ≤ 1.0 | ≤ 1.0 | ≤ 0.045 | ≤ 0.03 | 10.5-11.75 | ≤ 0.50 |

| 409 L | C % | Si % | Mn % | P% | S% | Cr% | Ni% | N% |

| ASTM | ≤ 0.03 | ≤ 1.0 | ≤ 1.0 | ≤ 0.040 | ≤ 0.03 | 10.5-11.75 | — | — |

| JIS | ≤ 0.03 | ≤ 1.0 | ≤ 1.0 | ≤ 0.040 | ≤ 0.03 | 10.5-11.70 | — | — |

| EN | ≤ 0.03 | ≤ 1.0 | ≤ 1.0 | ≤ 0.040 | ≤ 0.015 | 10.5-12.50 | — | ≤ 0.030 |

| GB | ≤ 0.03 | ≤ 1.0 | ≤ 1.0 | ≤ 0.040 | ≤ 0.03 | 10.5-11.75 | — | — |

Mechanical Properties of 409&409L Stainless Steel Sheets&Plates

| Mechanical Properties | 409 Stainless Steel | 409 L Stainless Steel |

| T.S.(MPa) | ≥415 | ≥170 |

| Y.S.(MPa) | ≥240 | ≥415 |

| L.(%) | ≥20 | ≥25 |

| HB | ≤88 | ≤170 |

| HRB | ≤89 | ≤88 |

| HBW | ≤180 | ≤183 |

Physical Properties of 409&409L Stainless Steel Sheets&Plates

| Physical Properties | 409 Stainless Steel | 409 L Stainless Steel |

| Density (g/cm³) | 7.85 | 7.8 |

| Melting point (℃) | 1450-1510 | 1450-1510 |

| Thermal conductivity (W/m-K) | 26.1 | 26,3 |

| Elastic Modulus(GPa) | 0.6 | 0.6 |

| Coefficient of thermal expansion (10^-6/K) | 10.2 | 10.2 |

| Specific Heat Capacity, J/(g·K) | 0.46 | 0.46 |

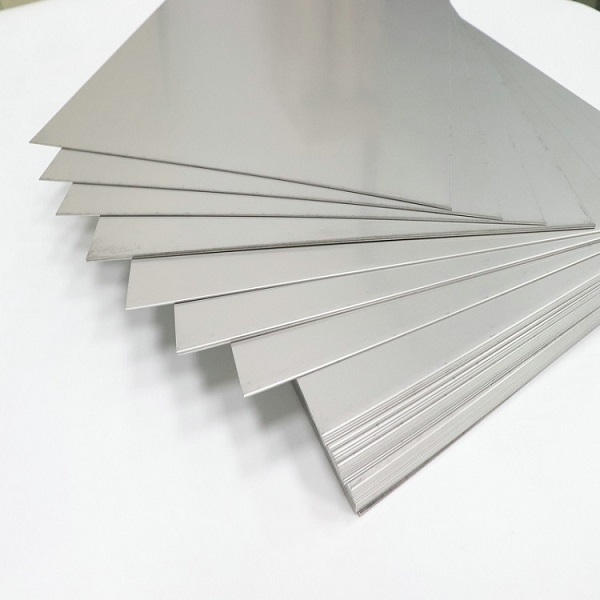

Product Description of 409&409L stainless steel sheets

409 stainless steel, initially intended for automotive exhaust systems, is prized for its corrosion resistance.

409 and 409L stainless steel sheets offer affordability along with high corrosion resistance and weldability. With a lower chromium content, 409 stainless steel sheets mainly comprise iron, carbon, chromium, and titanium. The addition of titanium enhances corrosion resistance and weldability. On the other hand, 409L stainless steel sheets contain higher titanium and lower chromium content compared to 409, resulting in improved welding properties and corrosion resistance.

Although stainless steel excels in many applications, its temperature resistance typically ranges from 500 to 750 degrees Celsius, limiting its suitability for high-temperature environments.

409&409L Stainless Steel sheet Stock Available

SS 409 sheet Mirror Finish

Cold rolled, bright annealed 409 sheet

SS 409 Perforated sheet

Grade Prime SS 409 sheet

Satin finish Stainless Steel 409 sheet

Embossed ss 409 sheet

Baosteel Stainless Steel 409 sheet

Laser cutting ss 409 sheet

SS URANUS B6 409 sheet

Super Austenitic SS 409 sheet

409 Stainless Steel Golden Laser Pattern sheet

SS 409 Rose Golden sheet

Hot Selling AISI SS 409 sheet

Decorative Stainless Steel 409 sheet

ASTM A240 409 sheet

2B SUS SS 409 sheet

Brushed or dull polished Stainless Steel 409 sheet

SS DIN 1.4571 sheet

Passenger Elevator Cabin SS 409 sheet

Cr Stainless Steel 409 sheet

409 Stainless Steel Blank sheet

3mm Cold Rolled AISI SS 409 sheet

Cold rolled, heat treated 409 sheet

Super thin-Mirror surface BA ss 409 sheet

Cut to Size Stainless Steel 409 sheet

Surface Polishing SS 409 sheet

Hair Line Finish SS 409 sheet

Tisco Stainless Steel 409 sheet

ASTM B625 409 sheet

SEW 400 Stainless Steel 409 sheet

Scotch Brite SS 409 sheet

Mirror Finish SS 409 sheet

SS 409 sheet Gold Brush Finish

Black SS 409 sheet 4mm Thick

Hot Rolled Stainless Steel 409 sheet

No. 4 PVC Coated SS 409 sheet

18 Gauge SS 409 sheet

AISI stainless steel 409 armor sheet

SS 409 Mill Test Certificate sheet

ASTM A240 Stainless Steel 409 sheet

Cold Rolled No.1 Finish SS 409 sheet

AISI SS 409 sheet

Patterned Stainless Steel 409 sheet

Cheap cold rolled ss 409 sheet with best price

Decorative hairline inox cold rolled ss 409 sheet

409 Stainless Steel CR sheet

Mill Supply SS 409 sheet

SS 409 Embossed sheet

Surface coated Stainless Steel 409 sheet

Stainless Steel Corrugated 409 sheet

Chequered Stainless Steel 409 sheet

A 240 Chequered 409 sheet

Aperam Stainless Steel 409 sheet

ASTM A240 409 sheet

Features of 409&409L Stainless Steel Sheets&Plates

features of 409 stainless steel sheet and plate

- Excellent Mechanical Properties: Due to its ferritic stainless steel nature, 409 exhibits excellent mechanical properties suitable for various engineering and structural applications.

- High Temperature and Corrosion Resistance: Maintains performance in high-temperature and corrosive environments, making it an ideal choice for automotive exhaust systems.

- Prone to Rusting: Despite good corrosion resistance, 409 stainless steel sheets are susceptible to rusting in certain environments, limiting their use in decorative applications.

features of 409L stainless steel sheet and plate

- Low Carbon Environmental Protection: Compared to 409, 409L has a lower carbon content, making it perform better in terms of environmental protection and corrosion resistance.

- Higher High-Temperature Resistance: Due to its low carbon content and optimization of other alloying elements, 409L can maintain its performance at higher temperatures, reducing exhaust emissions.

- Good Corrosion Resistance: Suitable for extending the lifespan of automobiles and lightweighting vehicles, as it can maintain its structure and appearance in harsh environments.

- Ease of Processing and Recycling: 409L stainless steel sheets have good machinability and are environmentally friendly materials that can be recycled, aligning with modern sustainable development trends.

Application of 409&409L Stainless Steel Sheets&Plates

Automotive Exhaust Systems

Type 409 and Type 409L stainless steel sheets are used to make mufflers, resonators, and other components of automotive exhaust systems. They offer good corrosion resistance, heat resistance, and formability, making them ideal for this application.

Heat Exchangers

Type 409 and Type 409L stainless steel sheets are used to make heat exchangers for various industrial applications. They offer good resistance to corrosion and heat, making them suitable for this application.

Bus and Truck Bodies

Type 409L stainless steel sheets are used to make bus and truck bodies due to their excellent corrosion resistance and low maintenance requirements.

Structural Components

Type 409 and Type 409L stainless steel sheets are used to make various structural components such as bridges, building facades, and industrial equipment. They offer good formability and cost-effectiveness, making them a popular choice for this application.

Kitchen Equipment

Type 409 and Type 409L stainless steel sheets are used to make kitchen equipment such as sinks, backsplashes, and countertops. They offer good resistance to corrosion and heat, making them ideal for this application.

Stainless Steel Sheets Supplier — HUAXIAO

Thank you very much for taking the time to read this product introduction. We believe that through this article, you have gained a deeper understanding of 409 and 409L stainless steel sheets. Whether for everyday use in life or professional requirements in industrial manufacturing, choosing the right materials is crucial. We look forward to providing you with valuable references and suggestions in your material selection process.

Huaxiao Metal is a company with over 15 years of experience in exporting stainless steel products. As a professional stainless steel supplier, we are committed to providing customers with high-quality and stable-performance 409 and 409L stainless steel sheets. Simply inform us of the required dimensions, quantity, and grade, and we will promptly provide you with an accurate quotation.

Our competitive Stainless Steel Sheets

We will answer your email in 24 hours!

FAQ

The liquid-to-solid phase transition of 409L steel occurs at a narrow temperature range, below 30°C. Upon solidification, the steel forms fine equiaxed crystals due to rapid cooling and non-spontaneous nucleation on the crystallizer’s surface. This promotes high formation rates, resulting in equiaxed grain formation rather than columnar crystals. The steel exhibits a minimal overcooling zone, preventing the growth of columnar crystals.

During pouring, if the slab temperature drops to 1100°C with high carbon content, carbides form, along with chromium-depleted areas and a small amount of δ phase. Despite the appearance of two distinct phases, the low carbon content of 409L steel minimizes the impact on performance.

The absence of an α → γ phase transition in 409L steel results in easy grain growth, forming a rough ferrite structure with reduced strength. This can lead to issues like elbows during casting, affecting manufacturing efficiency. The primary concern with 409L steel crystallization is the formation of coarse grains, as there is minimal γ phase presence at high temperatures.

- Carbon Content: 409 stainless steel has a higher carbon content, while 409L is a low-carbon version with lower carbon content. This results in superior corrosion resistance for 409L, especially in high-temperature and harsh environments. In comparison, the corrosion resistance of 409 stainless steel is slightly inferior to that of 409L.

- Corrosion Resistance: Due to the difference in carbon content, 409L stainless steel sheet exhibits better corrosion resistance, particularly in high-temperature and harsh environments. In contrast, the corrosion resistance of 409 stainless steel is slightly lower than that of 409L.

- High-Temperature Resistance: 409L stainless steel sheet, with its low carbon content and optimized alloy elements, has higher resistance to high temperatures. This allows it to maintain its structure and performance at higher temperatures, reducing exhaust emissions.

Processing 409 and 409L stainless steel sheets is relatively moderate in difficulty. Both materials have good machinability and can be processed using conventional techniques such as cutting, bending, and welding. However, as they are both ferritic stainless steels, they may be slightly more challenging to cold work compared to austenitic stainless steels. Additionally, it is important to control temperature and deformation during the processing to avoid excessive stress and cracking. Overall, processing 409 and 409L stainless steel sheets requires some technical expertise and experience but is not particularly difficult.

The lifespan of 409 and 409L stainless steel sheets depends on various factors, including the operating environment, material quality, manufacturing processes, and maintenance practices. Generally, when used under appropriate conditions and properly maintained, these stainless steel sheets can have a relatively long lifespan. However, the specific duration varies depending on different conditions, making it difficult to provide exact numbers.

- Regular Cleaning: Remove surface oil, dust, and corrosion, keeping the surface clean.

- Avoid Impact: Avoid contact with sharp objects to prevent surface scratches and damage.

- Control the Environment: Avoid prolonged exposure to humid and corrosive environments.

- Appropriate Use: Use according to design purposes and load capacity, avoiding overloading or improper use.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WeChat:+86 13381673250

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China