Do you have any questions about our products or are you looking for a professional 301 stainless steel sheets supplier?

301 Stainless Steel Sheets and Plates Supplier

- Specification: ASTM 12Cr17Ni7, GB 1Cr17Ni7, UNS S30110, ASTM 301, UNS S30100, AISI 30301, EN 1.4319, EN X3CrNi17-8, JIS SUS301, AFNOR Z12CN17.07, UNS 301S21, ISO 14, GOST 09X17H7Ю.

- Features: Offers high strength, corrosion resistance, and increased hardness through cold working.

- Thickness: 0.05mm – 200mm

- Width: 600mm – 2000mm

- Length: 500mm-12000mm

- Finish: 2B, 2D, Black, NO.1, Anneal pickling

- MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Factory Price 301 stainless steel sheets Now

301 Stainless Steel sheet and plate Data Sheet

301 Grade Description in Different Standard

ISO Name | ASTM | DIN / EN | JIS | GB | Other |

X5CrNi17–7 | S30100 / 301 | 1.4319 | SUS301 | S30110 | 06Cr17Ni7 |

301 Grade Chemical Components in Different Standard

301 | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % |

ASTM | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | 0.1 |

DIN/EN | 0,07 | 1,00 | 2,00 | 0,045 | 0,030 | 6,0-8,0 | 16,0-18,0 | – | 0,1 |

JIS | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | – |

GB | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | 0.1 |

301 Mechanical Property in Different Standard

301 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 95 | 217 | – |

JIS | 205 | 520 | 40 | 207 | 95 | – | 218 |

GB | 205 | 515 | 40 | – | 95 | 217 | 218 |

301 Physical Property in Different Standard

| 301 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.93 | 1400-1450 | 16.3 | 17.2 |

| JIS | 7.93 | 1399-1454 | 16.3 | 17.2 |

| EN | 7.9 | 1400-1450 | 16.2 | 17.2 |

| GB | 7.93 | 1398-1454 | 16.3 | 17.2 |

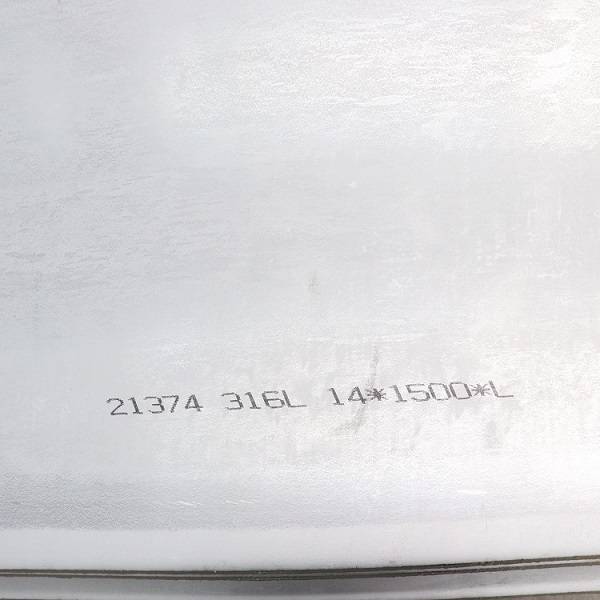

Production Range of 301 stainless steel sheets and plates

-Cold Rolled 301 Stainless Steel Sheet and Plate, Cold rolled 301 sheets, Cold rolled 301 Plate

- Thickness: 0.05mm – 3.0mm

- Width: 600mm – 2000mm, the narrowed products pls check in strip products

- Length: 1000mm-6000mm

- Finish: 2B, 2D

-Hot Rolled 301 Stainless Steel Sheet and Plate, Hot Rolled 301 Sheet, Hot Rolled 301 Plate,301 PMP, 301 CMP

- Thickness: 1.2mm – 200mm

- Width: 600mm – 3200mm

- Length: 500mm – 12000mm

- Finish: Black, NO.1, Anneal pickling

Product Description of 301 stainless steel sheets and plates

301 stainless steel sheet and plate is a high-quality austenitic stainless steel with a unique composition of 17% chromium, 7% nickel, and carbon, giving it distinctive properties. Despite its moderate chromium and nickel content, its strength and hardness significantly increase after cold processing, along with exhibiting magnetism. This makes 301 stainless steel sheets stand out in various applications, especially in fields requiring high strength and durability, such as trains, automobiles, aircraft, and conveyor systems.

Compared to 304 metal, 301 stainless steel sheet demonstrates higher strength and hardness after cold processing, making it more suitable for manufacturing components like stretch batteries, springs, and displays that demand high strength and durability. Additionally, although it is an austenitic stainless steel, proper deformation processing can further enhance its durability and hardness while maintaining excellent flexibility.

It is worth mentioning that 301 stainless steel sheet also boasts excellent rust resistance, ensuring stability and aesthetics in various climate conditions. However, it is important to note that this metal exhibits poor resistance to certain media such as alkalis and acid salts, making it unsuitable for specific environments, such as Arctic conditions.

Furthermore, 301 stainless steel sheets exhibit outstanding high-temperature resistance, and due to their lighter weight and thinner wall thickness, they can reduce the weight and thickness of welding equipment parts. Additionally, this metal possesses the characteristic of work hardening, providing better safety protection when subjected to external forces.

Features of 301 Stainless Steel Sheets&Plates

- Strength and Hardness: After cold processing, the strength and hardness of 301 stainless steel sheet significantly increase. This characteristic makes it excel in applications requiring high loads, such as manufacturing springs, stretch batteries, and other components.

- Corrosion Resistance: 301 stainless steel sheet exhibits good rust resistance under atmospheric conditions. However, it is important to note that its corrosion resistance in certain specific environments, such as acidic or alkaline chemical media, may be poor. Therefore, it may not be suitable for use in some highly corrosive environments.

- High-Temperature Performance: 301 stainless steel sheet has excellent oxidation resistance and can withstand temperatures as high as 840°C (intermittent use) or even 900°C (continuous use). However, when exposed to temperatures above 400°C, its work hardening effect may gradually diminish.

- Machinability: 301 stainless steel sheet is easily cold formed and strengthened. Through cold deformation processing, its strength and hardness can be increased while maintaining sufficient plasticity and toughness. This makes it highly popular in applications requiring complex machining and forming.

- Magnetism: In the annealed state, 301 stainless steel sheet is non-magnetic, but after cold processing, it exhibits strong magnetism. This characteristic may be an important consideration in certain applications.

Application of 301 Stainless Steel Sheets&Plates

Automotive Industry

301 stainless steel plates with high strength and excellent corrosion resistance, are widely used in the manufacture of auto bodies, chassis, exhaust systems, and other components.

Electronics and Electrical Industry

301 stainless steel sheets with a flat surface, good gloss, and corrosion resistance, suitable for the manufacture of cell phones, computers, refrigerators, microwave ovens, and other electronic and electrical products shells and parts.

Chemical and Marine Engineering

301 stainless steel sheets have good corrosion resistance and oxidation resistance, suitable for the manufacture of chemical equipment, marine platforms, seawater treatment equipment, and other projects that require corrosion resistance.

Food and Pharmaceutical Industry

301 stainless steel sheets have good surface flatness and sanitary properties, and are widely used in the manufacture of food machinery, pharmaceutical equipment, and other products that require sanitary requirements.

Construction and Decoration Industry

301 stainless steel plates with good decorative properties, suitable for the manufacture of stair handrails, decorative sculpture, interior decoration, and other products.

Huaxiao Stainless Steel Sheets Supplier

Thank you very much for taking the time to read the detailed introduction about the 301 stainless steel sheet. Through this article, we believe you have gained a clearer and deeper understanding of the characteristics, advantages, and applications of the 301 stainless steel sheet. As a professional stainless steel supplier, Huaxiao is committed to providing high-quality and diversified stainless steel products to meet your needs in different fields. Whether you need stainless steel products of any grade, size, or shape, Huaxiao Metal will be dedicated to serving you. If you have any questions or requirements, please feel free to contact us, and we will promptly provide you with the most satisfactory solutions. Once again, thank you for your attention and support to Huaxiao Stainless Steel. We look forward to cooperating with you!

We will answer your email in 24 hours!

FAQ

Composition and Structure:

- 301 stainless steel sheet is an austenitic stainless steel containing moderate amounts of chromium and nickel, and its strength and hardness increase after cold processing.

- 310 stainless steel sheet is a chromium-nickel stainless steel with higher chromium and nickel content, exhibiting excellent corrosion resistance and high-temperature oxidation resistance.

Corrosion Resistance:

- 301 stainless steel sheet may exhibit poor corrosion resistance in certain specific environments, such as acidic or alkaline chemical media.

- 310 stainless steel sheet, due to its higher chromium and nickel content, offers better corrosion resistance, particularly suitable for high-temperature and strong corrosive environments.

High-Temperature Performance:

- Although 301 stainless steel sheet can withstand high temperatures, its high-temperature performance is relatively weaker, typically used below 840°C.

- 310 stainless steel sheet has superior high-temperature performance, capable of withstanding higher temperatures, commonly used for manufacturing components in high-temperature environments.

Composition:

- 301 stainless steel sheet is mainly composed of 18% chromium, 8% nickel, and contains a certain amount of carbon.

- 304 stainless steel sheet contains 18% chromium, 8% nickel, but has a relatively lower carbon content.

Mechanical Properties:

- 301 stainless steel sheet, due to its higher chromium content, lesser nickel content, and moderate amount of carbon, exhibits higher strength and hardness, with excellent work hardening properties (non-magnetic).

- 304 stainless steel sheet, with its lower carbon content, has relatively softer mechanical properties, but its wear resistance and fatigue strength are superior to 301 stainless steel.

Corrosion Resistance:

- 301 stainless steel sheet may exhibit poor corrosion resistance in certain specific environments, such as acidic or alkaline chemical media.

- 304 stainless steel sheet, due to its higher chromium and nickel content, as well as lower carbon content, possesses better corrosion resistance and finds wide applications in equipment and components requiring excellent corrosion resistance.

Composition:

- 301 stainless steel sheet is primarily composed of 17% chromium, 7% nickel, and a moderate amount of carbon.

- 316 stainless steel sheet contains higher levels of chromium (16-18%) and nickel (10-14%), with the addition of 2-3% molybdenum to enhance its corrosion resistance properties.

Corrosion Resistance and High-Temperature Resistance:

- 301 stainless steel sheet may exhibit poor corrosion resistance in certain specific environments, such as acidic or alkaline chemical media, and its high-temperature resistance is relatively weaker.

- 316 stainless steel sheet, due to its high chromium, high nickel content, and the addition of molybdenum, possesses stronger corrosion resistance and high-temperature resistance, particularly showing superior performance in seawater and certain chemical environments.

Mechanical Properties:

- 301 stainless steel sheet exhibits higher strength and hardness, making it easy to increase its strength through cold working, suitable for applications requiring higher hardness and strength.

- 316 stainless steel sheet also has good ductility, toughness, and cold deformation ability, while its strength and corrosion resistance make it perform exceptionally well in various applications.

Processing 301 stainless steel sheets is relatively easy due to its good ductility, toughness, and cold deformation ability. During cold working, 301 stainless steel sheets exhibit a high rate of work hardening, resulting in a significant increase in tensile strength and yield strength with increasing cold working amount, making it easy to shape and process. However, it is important to note that due to the relatively poor corrosion resistance of 301 stainless steel sheets in certain specific environments, it is necessary to avoid using corrosive media such as strong acids and alkalis during the processing.

The three major series of stainless steel are the 200 series, 300 series, and 400 series. Among them, the 300 series is the most commonly used stainless steel series, while the 400 series and 200 series can serve as alternatives to the 300 series within certain ranges. It is worth noting that the 400 series, due to the absence of nickel elements, is technically stainless iron and can therefore be attracted by a magnet.