Seamless 201 Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

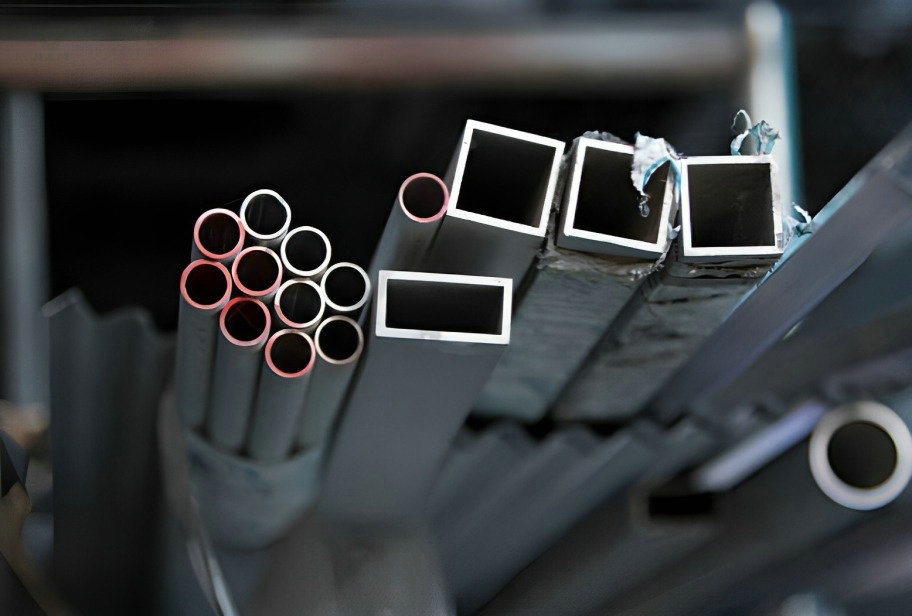

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 202 Stainless Steel Pipe

Seamless 202 stainless steel pipes are crafted from high-quality raw materials, offering a range of sizes and thicknesses to choose from. With a chemical composition of 17-19% chromium, 4-6% nickel, and 7.5-10% manganese, these pipes possess excellent corrosion resistance, high-temperature strength, and low maintenance requirements. Widely used in industrial heating systems, water utilities, food and beverage processing, medical equipment manufacturing, and chemical processing industries, Seamless 202 Stainless Steel Pipes cater to diverse applications.

specification Of Seamless 202 Stainless Steel Pipe

Chemical Components Of Seamless 202 Stainless Steel Pipe

| 202 | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Mo % |

| ASTM | 0.15 | 1 | 7.5-10.0 | 0.06 | 0.03 | 4.0-6.0 | 17.0-19.0 | 0.25 | – |

| DIN/EN | 0,15 | 1,00 | 7,5-10,5 | 0,045 | 0,015 | 4,0-6,0 | 17,0-19,0 | 0,05-0,25 | – |

| JIS | 0.15 | 1 | 7.5-10.0 | 0.06 | 0.03 | 4.0-6.0 | 17.0-19.0 | 0.25 | – |

| GB | 0.15 | 1 | 7.5-10.0 | 0.05 | 0.03 | 4.0-6.0 | 17.0-19.0 | 0.05-0.25 | – |

Mechanical Property Of Seamless 202 Stainless Steel Pipe

| 202 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 260 | 620 | 40 | – | – | 241 | – |

| JIS | 275 | 520 | 40 | – | 95 | 207 | 218 |

| GB | – | – | – | – | – | – | – |

Physical Property Of Seamless 202 Stainless Steel Pipe

| Property | value |

| Density | 7.81 g/cm³ |

| Melting Point | 1399-1420℃ |

| Thermal Conductivity | 16.3 W/m·K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Conductivity | 2.50% IACS |

| Modulus of Elasticity | 193 GPa |

| Poisson’s Ratio | 0.28 |

| Coefficient of Thermal Expansion | 16.3µm/m·°C |

| Magnetic Permeability | <1.02 |

| Hardness (Rockwell B) | HRB < 95 |

characteristics Of Seamless 202 Stainless Steel Pipe

Corrosion resistance is a prominent characteristic of Seamless 202 Stainless Steel Pipe. Thanks to its composition, which includes a chromium content of 17-19%, the pipe demonstrates impressive resistance to various corrosive environments. This quality makes it suitable for applications in industries exposed to challenging conditions, such as water utilities, chemical processing, and marine environments. The ability to withstand corrosion ensures the longevity and reliability of the pipe, contributing to its widespread use in diverse applications.

Seamless 202 Stainless Steel Pipe exhibits notable high-temperature strength due to its composition, featuring a chromium content of 17-19% and nickel content of 4-6%. This combination of elements contributes to the pipe’s ability to maintain structural integrity and mechanical properties even at elevated temperatures. This characteristic makes it suitable for applications in industrial heating systems, where pipes are subjected to varying levels of heat stress. The high-temperature strength of Seamless 202 Stainless Steel Pipe ensures its performance and reliability in demanding thermal environments.

Seamless 202 Stainless Steel Pipe displays magnetic properties due to its composition, which includes a significant amount of manganese (7.5-10%). The presence of manganese in the alloy contributes to the development of magnetic behavior. While 202 stainless steel is not as strongly magnetic as some other stainless steel grades, its magnetic characteristics make it suitable for certain applications where magnetic properties are desired. This attribute can be advantageous in industries such as electronics, automotive, and manufacturing, where magnetic properties are utilized for various purposes.

Seamless 202 Stainless Steel Pipe offers excellent formability, allowing it to be easily shaped and fabricated into various configurations. Its malleable nature makes it suitable for processes like bending, rolling, and shaping without compromising its structural integrity. This characteristic enhances its versatility, enabling the creation of complex and intricate designs. The combination of good formability and other desirable properties makes seamless 202 stainless steel pipes a favorable choice for applications that require intricate or customized shapes and structures.

Seamless 202 Stainless Steel Pipe boasts a visually appealing appearance that combines modern aesthetics with practical functionality. Its smooth surface finish contributes to an attractive and polished look, making it suitable for applications where appearance matters. This characteristic is particularly valuable in industries like architecture, interior design, and consumer goods manufacturing, where the visual appeal of the material plays a significant role. The seamless 202 stainless steel pipe’s pleasing appearance enhances its versatility, allowing it to seamlessly blend into various design styles and settings while delivering reliable performance and durability.

application Of Seamless 202 Stainless Steel Pipe

Industrial Heating Systems

In industrial heating systems, Seamless 202 Stainless Steel Pipe plays a crucial role in transporting hot fluids, gases, and steam. Its high-temperature strength and corrosion resistance make it well-suited for handling the extreme conditions of these systems. The pipe's durability and ability to maintain its structural integrity at elevated temperatures ensure efficient heat transfer, contributing to the effective operation of various industrial processes such as heat exchangers, boilers, and furnaces. Additionally, its resistance to corrosion from the byproducts of combustion and other aggressive substances encountered in industrial heating applications further enhances its reliability and longevity in these systems.

Water Utilities

Seamless 202 Stainless Steel Pipe finds significant utility in water distribution and treatment systems. Its corrosion-resistant properties make it an ideal choice for transporting potable water and various fluids within water utility networks. The pipe's resistance to rust and chemical degradation ensures the integrity of the water supply, preventing contamination and maintaining water quality. Whether used for pumping, distribution, or treatment processes, the pipe's robustness and corrosion resistance contribute to the reliability and long-term performance of water utility infrastructure, ensuring the safe delivery of clean water to communities.

Food and Beverage Processing

Seamless 202 Stainless Steel Pipe plays a pivotal role in the food and beverage processing industry, ensuring the safe and hygienic transportation of liquids and gases. Its corrosion-resistant properties make it suitable for handling various food products, beverages, and processing fluids without compromising their quality. The pipe's smooth interior surface prevents the accumulation of contaminants and facilitates easy cleaning, meeting stringent hygiene standards. Additionally, its formability allows for customization to fit specific processing needs, making it an essential component in ensuring the integrity and safety of food and beverage production processes.

Medical Equipment Manufacturing

In the realm of medical equipment manufacturing, Seamless 202 Stainless Steel Pipe finds valuable applications due to its exceptional properties. This pipe offers a high degree of corrosion resistance, ensuring the safe transportation of fluids and gases in medical devices and equipment. Its formability allows for precision shaping, enabling the creation of intricate components required in various medical apparatuses. The non-magnetic nature of the stainless steel ensures compatibility with sensitive medical equipment that demands minimal interference from external magnetic fields. With its hygienic surface and resistance to corrosion, Seamless 202 Stainless Steel Pipe contributes to the reliability and safety of medical equipment used in diverse healthcare settings.

Chemical Processing Industries

In chemical processing industries, Seamless 202 Stainless Steel Pipe serves as a crucial component due to its unique attributes. Its excellent corrosion resistance makes it ideal for handling various corrosive chemicals and substances, ensuring the integrity of the piping system. The high-temperature strength of the pipe allows it to withstand the demanding conditions often present in chemical processing operations. Its formability enables the creation of customized configurations required for intricate chemical processes. Additionally, the non-magnetic property of the stainless steel prevents unwanted reactions or interferences with sensitive chemical reactions. The Seamless 202 Stainless Steel Pipe's reliability, durability, and resistance to harsh chemical environments contribute to the safe and efficient functioning of chemical processing facilities.

FAQ

Certainly! Seamless 202 Stainless Steel Pipe exhibits remarkable high-temperature strength, making it a reliable choice for applications demanding thermal stability. Its inherent composition, with chromium and nickel as key alloying elements, contributes to its ability to withstand elevated temperatures without compromising structural integrity.

Seamless 202 Stainless Steel Pipe’s capacity to endure high temperatures stems from its unique metallurgical properties. The presence of chromium enhances its resistance to oxidation, forming a protective layer that shields the pipe from scaling and deterioration even when exposed to elevated heat. Additionally, the inclusion of nickel in the alloy composition further bolsters its resistance to thermal stress and deformation.

In industrial settings such as industrial heating systems, where pipes are subjected to intense heat, Seamless 202 Stainless Steel Pipe excels due to its exceptional thermal stability. Whether it’s conveying heated fluids or gases in manufacturing processes, the pipe maintains its strength and performance, minimizing the risk of structural failure under high-temperature conditions.

For applications involving heat-intensive operations, industries can rely on Seamless 202 Stainless Steel Pipe to ensure efficient heat transfer while maintaining its structural integrity. Its ability to withstand high temperatures, coupled with its corrosion resistance, provides a durable and long-lasting solution for various industries.

As stainless steel pipe suppliers recognize the demand for high-temperature-resistant materials, Seamless 202 Stainless Steel Pipe stands as a dependable choice that meets the rigorous requirements of elevated thermal environments.

Seamless 202 Stainless Steel Pipe exhibits notable high-teavmperature strength due to its composition, featuring a chromium content of 17-19% and nickel content of 4-6%. This combination of elements contributes to the pipe’s ability to maintain structural integrity and mechanical properties even at elevated temperatures. This characteristic makes it suitable for applications in industrial heating systems, where pipes are subjected to varying levels of heat stress. The high-temperature strength of Seamless 202 Stainless Steel Pipe ensures its performance and reliability in demanding thermal environments.

Seamless 202 Stainless Steel Pipe is known for its exceptional corrosion resistance, high-temperature strength, and durability, which contribute to its relatively low maintenance requirements. While it is designed to withstand various environmental conditions, a certain level of maintenance is recommended to ensure its longevity and optimal performance.

Routine maintenance practices for Seamless 202 Stainless Steel Pipe are generally straightforward. Regular inspections to identify signs of corrosion, surface damage, or any potential leaks are crucial. If the pipe is exposed to harsh or corrosive environments, more frequent inspections might be necessary.

Cleaning the pipe’s surface periodically to remove dirt, debris, and any contaminants can help maintain its appearance and prevent the buildup of corrosive substances. Mild detergents and water can usually suffice for cleaning.

In areas where the pipe is subjected to high temperatures, it’s important to monitor for any signs of thermal stress, such as discoloration or distortion, which could affect its structural integrity.

Collaborating with stainless steel pipe suppliers can provide valuable guidance on maintenance practices specific to Seamless 202 Stainless Steel Pipe. They can offer recommendations based on the intended application and environmental conditions.

By following recommended maintenance practices and collaborating with experienced stainless steel pipe suppliers, businesses can ensure that their Seamless 202 Stainless Steel Pipe continues to perform optimally throughout its operational life, maintaining its exceptional properties and contributing to the efficiency of various industrial processes.

The cost of Seamless 202 Stainless Steel Pipe is influenced by several factors, including the specific application, size, quantity, and market conditions. While stainless steel is generally considered a higher-cost material compared to some other materials, it offers a range of unique benefits that can justify its investment.

Seamless 202 Stainless Steel Pipe’s initial cost might be higher than that of certain non-metallic materials. However, it’s important to consider the long-term cost-effectiveness. Stainless steel’s exceptional corrosion resistance significantly reduces maintenance and replacement costs over time, making it a cost-effective choice for applications where durability and longevity are crucial.

Furthermore, Seamless 202 Stainless Steel Pipe is suitable for a wide range of applications, including those requiring high-temperature resistance, chemical compatibility, and hygienic conditions. Its versatility and resistance to various environmental factors contribute to minimizing the need for frequent replacements and repairs, which can be costly.

Collaborating with experienced stainless steel pipe suppliers can help in understanding the cost considerations and making informed decisions. Suppliers can provide insights into material pricing trends, options for customization, and the overall cost-effectiveness of using Seamless 202 Stainless Steel Pipe for specific applications.

While the initial investment might be higher compared to some materials, the long-term savings in terms of maintenance, durability, and performance make Seamless 202 Stainless Steel Pipe a smart choice for many industries seeking reliable and enduring solutions.

The manufacturing process of Seamless 202 Stainless Steel Pipe involves several key steps to ensure the production of high-quality, seamless tubes that meet industry standards. Here’s an overview of the process:

- Raw Material Selection: High-quality stainless steel raw materials are carefully selected. In the case of Seamless 202 Stainless Steel Pipe, the raw material would be 202-grade stainless steel, which typically contains chromium, nickel, and manganese for corrosion resistance and strength.

- Melting and Casting: The selected stainless steel is melted in electric arc furnaces. The molten metal is then cast into billets, which are solidified and then cut into the desired lengths.

- Hot Extrusion: The billets are heated and then passed through a piercing mill to create a hollow shell known as a “bloom.” The bloom is further elongated and reduced in diameter using a series of rollers in a hot extrusion process. This forms the basic shape of the pipe.

- Rotary Piercing and Tube Rolling: The pierced bloom is then subjected to rotary piercing to create a hollow tube. This tube is further elongated and reduced in size using a series of sizing rolls to achieve the desired dimensions and wall thickness.

- Heat Treatment: The tube is subjected to heat treatment processes, including annealing, to enhance its mechanical properties, eliminate internal stresses, and improve overall quality.

- Finishing Processes: The tube’s surface is cleaned, polished, and inspected for defects. It may undergo additional processes such as pickling or passivation to remove any oxides or contaminants.

- Testing and Quality Control: The finished tube undergoes various tests to ensure its compliance with industry standards, including dimensional accuracy, mechanical properties, and corrosion resistance.

- Cutting and Packaging: The seamless tube is cut into specified lengths and prepared for packaging. It may be bundled, labeled, and protected to prevent damage during transportation.

- Final Inspection and Certification: The final product is subjected to rigorous inspection to ensure it meets the required specifications. Once approved, the Seamless 202 Stainless Steel Pipe is certified for its quality and characteristics.

Collaborating with reputable stainless steel pipe suppliers ensures that the entire manufacturing process adheres to industry standards and results in high-quality seamless tubes that can be used in a variety of applications.

Seamless 202 Stainless Steel Pipe and 201 Stainless Steel Seamless Pipe are two distinct grades of stainless steel pipes that exhibit differences in their composition, characteristics, and applications:

Chemical Composition:

- Seamless 202 Stainless Steel Pipe: Contains approximately 17-19% chromium, 4-6% nickel, and 7.5-10% manganese. This composition provides excellent corrosion resistance, high-temperature strength, and low maintenance requirements.

- 201 Stainless Steel Seamless Pipe: Comprises approximately 16-18% chromium, 3.5-5.5% nickel, and lower manganese content. It offers good corrosion resistance and is often used in decorative applications.

Corrosion Resistance:

- Seamless 202: Offers excellent corrosion resistance due to its chromium content.

- 201 Stainless Steel: Provides good corrosion resistance in less aggressive environments.

Applications:

- Seamless 202: Widely used in industrial heating systems, water utilities, food and beverage processing, medical equipment manufacturing, and chemical processing industries due to its superior corrosion resistance, strength, and durability.

- 201 Stainless Steel: Often employed in decorative applications, such as architecture and furniture, due to its reflective surface and moderate corrosion resistance.

Strength and Durability:

- Seamless 202: Offers good strength and durability, suitable for various industrial applications.

- 201 Stainless Steel: Provides adequate strength for decorative purposes and certain non-demanding applications.

Magnetic Properties:

- Seamless 202: Typically exhibits magnetic properties due to its higher nickel content.

- 201 Stainless Steel: Can exhibit magnetic properties depending on its processing history.

Formability:

- Seamless 202: Demonstrates good formability, making it suitable for various shaping processes.

- 201 Stainless Steel: Offers satisfactory formability for decorative and lightweight applications.

While both grades have their distinct advantages, Seamless 202 Stainless Steel Pipe is favored for its broader range of applications in industries requiring enhanced corrosion resistance, high-temperature strength, and durability. Conversely, 201 Stainless Steel Seamless Pipe is often chosen for its aesthetic appeal and suitability for decorative purposes. Careful consideration of the specific requirements of each application is crucial in selecting the appropriate grade. Collaborating with reputable stainless steel pipe suppliers ensures that the chosen grade meets the intended performance criteria.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China