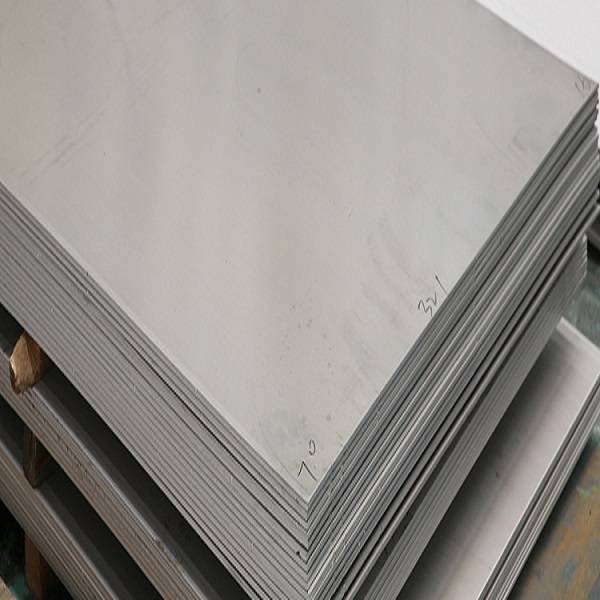

420 Stainless Steel Sheets and Plates Supplier

Do you have any questions about our products or are you looking for a professional 420 stainless steel sheets supplier?

Specifications: AISI 420 sheet, Fe 86.7%/Cr13.0%/C 0.3%, ASTM A240 SS 420 Sheet, ASME SA240, SS 420J1, SS 420J2, UNS S42000, 420/1.4034, DIN 1.4007

Features: Good corrosion resistance and high hardness, with excellent machinability.

Thickness: 0.05mm – 200mm; Width: 600mm – 2000mm; Length: 500mm – 12000mm

Standard: ASTM, JIS, SUS 420, AISI 420 stainless steel, GB…

Finish: 2B, BA, NO.1, NO.4, NO.8, 8K, mirror, Brush, SATIN

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Stainless Steel 420 Latest Price Now

420 Stainless Steel Sheets And Plates Data Sheet

chemical composition of 420 stainless steel

| 420 | C% | Si% | Mn% | P% | S% | Ni% | Cr% | Mo% |

| ASTM | 0.15-0.36 | 1 | 1 | 0.04 | 0.03 | 1 | 12-14 | 0.75 |

| JIS | 0.16-0.25 | 1 | 1 | 0.04 | 0.03 | 1 | 12-14 | – |

| GB | 0.16-0.25 | 1 | 1 | 0.035 | 0.03 | 1 | 12-14 | – |

physical property of 420 stainless steel

| 420 | Material Status | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM A240/A240M | Annealed | 415 | 690 | 20 | 183 | 88 | 200 | – |

| JIS G4304 | Annealed | 345 | 690 | 20 | 201 | 93 | – | – |

| GB/T 1220 | Annealed | 345 | 690 | 20 | 201 | – | – | – |

| ASTM A240/A240M | Hardened and tempered | 1470 | 1655 | 5 | 48 | – | – | – |

| JIS G4304 | Hardened and tempered | 1320 | 1740 | 10 | 57 | – | – | – |

| GB/T 1220 | Hardened and tempered | 1320 | 1740 | 10 | 57 | – | – | – |

Mechanical Property of 420 stainless steel

| 420 Stainless Steel | Material Status | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

|---|---|---|---|---|---|---|---|---|

| ASTM A240/A240M | Annealed | 415 | 690 | 20 | 183 | 88 | 200 | – |

| JIS G4304 | Annealed | 345 | 690 | 20 | 201 | 93 | – | – |

| GB/T 1220 | Annealed | 345 | 690 | 20 | 201 | – | – | – |

| ASTM A240/A240M | Hardened and Tempered | 1470 | 1655 | 5 | 48 | – | – | – |

| JIS G4304 | Hardened and Tempered | 1320 | 1740 | 10 | 57 | – | – | – |

| GB/T 1220 | Hardened and Tempered | 1320 | 1740 | 10 | 57 | – | – | – |

Note: The parameters are for reference only, and the specific parameters should also be based on the data provided by the actual manufacturer.

T.S. stands for tensile strength, Y.S. stands for yield, L. stands for elongation, HB stands for Brinell hardness, HRB stands for Rockwell hardness B, HBW stands for Brinell hardness W, and HV stands for Vickers hardness.

Size ranges vary by specification and specific order requirements;

inquire now for your specific needs.

Description of 420 stainless steel sheets and plates

420 stainless steel sheet is Martensitic stainless steel. Its main components are iron, carbon, chromium, and a small amount of molybdenum, manganese, silicon, and other elements, usually containing between 0.15% and 0.40% of carbon, while containing 12% to 14% of chromium. Due to its high carbon content, 420 stainless steel has high hardness and strength, as well as good corrosion and wear resistance. It is therefore widely used in the manufacture of high-strength, high-hardness, and corrosion-resistant parts and equipment.

Features of 420 Stainless Steel Sheets And Plates

- Wear Resistance: 420 stainless steel plate exhibits a certain level of wear resistance, making it suitable for applications where friction and abrasion are present. It can maintain stable performance for extended periods of time.

- Corrosion Resistance: It has good corrosion resistance, particularly in environments prone to atmospheric, steam, water, and oxidative acid corrosion, making it suitable for various corrosive media.

- High Hardness: 420 stainless steel plate has high hardness, allowing it to maintain good stability and durability under pressure or impact.

- Moderate Price: Compared to other types of stainless steel, the price of 420 stainless steel plate is moderate, making it a cost-effective stainless steel material.

Different Performance in Different Material Status

420 stainless steel sheets will have some changes in performance in different material states, mainly in the following aspects:

Strength and Hardness: The strength and hardness of 420 stainless steel sheets increase significantly after heat treatment, and the strength and hardness in the heat-treated state are much higher than in the cold-rolled state.

Toughness and Plasticity: The toughness and plasticity of 420 stainless steel sheets will be improved after annealing, and the toughness and plasticity in the annealed state are higher than in the quenched state.

Corrosion Resistance: 420 stainless steel sheets has different corrosion resistance in different states. In the heat treatment state, it is easy to produce chromium segregation at the grain boundaries, which affects its corrosion resistance. In the annealed state, the chromium is evenly distributed at the grain boundaries, so its corrosion resistance will be improved.

Processing Performance: The processing performance of 420 stainless steel in different states is also different. In the annealed state, 420 stainless steel has the best processing performance and is easily processed into various shapes; while in the quenched state, due to its higher hardness and strength, the processing difficulty also increases accordingly.

Applications of 420 Stainless Steel Sheets And Plates

Chemical and Pharmaceutical Industry: 420 stainless steel plates are commonly used in the manufacturing of chemical and pharmaceutical equipment due to their excellent corrosion resistance, resisting the corrosion of various chemicals and ensuring the stable operation of equipment.

Construction Sector: With its high strength and excellent corrosion resistance, 420 stainless steel plates find wide application in the construction industry, serving as decorative materials, railings, doors, windows, etc., offering both aesthetics and durability.

Transportation: In the transportation sector, 420 stainless steel plates are frequently utilized in the manufacturing of automotive components, ship fittings, etc., capable of withstanding high pressure and impact to ensure transportation safety.

Electrical and Electronic Industry: Due to its good conductivity and corrosion resistance, 420 stainless steel plates are widely used in the electrical and electronic industry for manufacturing components and enclosures of electrical equipment.

Stainless Steel Sheets Supplier ——Huaxiao Stainless Steel

This 420 stainless steel plate, with its outstanding wear resistance, corrosion resistance, and moderate price, has become a highly sought-after product in the market. Whether in mechanical manufacturing, electrical equipment, or transportation, it demonstrates excellent performance, providing reliable support for various applications.

As a company with over 15 years of experience in the stainless steel export industry, Huaxiao Stainless Steel provides you with the highest quality products and services. Equipped with multiple production lines, we can flexibly meet various customization needs for stainless steel products, including plates, coils, strips, pipes, bars, and more.

If you have any requirements for purchasing 420 stainless steel plates or other stainless steel products, please contact us immediately. We will offer you the most professional advice and the most competitive prices to ensure the smooth implementation of your procurement plans.

Inquire Now About Your Steel Needs ! We will answer your email in 24 hours!

FAQ

420 stainless steel can be heat treated to improve its mechanical properties and corrosion resistance. Common heat treatments include annealing and quenching.

Annealing: By heating and holding, the grain size of 420 stainless steel is made larger to relieve stress and improve ductility. This is usually done at 840°C-900°C and then cooled to room temperature.

Quenching: By rapid cooling, the organization of 420 stainless steel undergoes phase transformation, thus improving its hardness and strength. Quenching can be divided into two ways, oil quenching and water quenching, and is usually carried out at about 1000°C.

It is important to note that parameters such as temperature, time and cooling rate need to be controlled during heat treatment to ensure that the desired mechanical properties and organization are obtained. Improper heat treatment may lead to degradation or failure of the properties of 420 stainless steel. Therefore, specific process requirements and standard specifications should be understood before heat treatment is performed.

304 and 420 stainless steel are two different stainless steel materials that have different chemical compositions and mechanical properties and therefore differ in their use and applications.

Chemical Composition: 304 stainless steel mainly contains elements such as chromium, nickel, and small amounts of carbon and manganese, while 420 stainless steel mainly contains chromium and a certain amount of carbon. Due to the difference in chemical composition, the two stainless sheets of steel have different properties in terms of corrosion resistance, strength, hardness, etc.

Mechanical Properties: 420 stainless steel is harder and more resistant to wear than 304 stainless steel, but its bendability and ductility are poor. 304 stainless steel, on the other hand, has better bendability and ductility and is usually used to manufacture products that require flexibility.

Application Areas: 304 stainless steel is widely used in kitchenware, decorative materials, chemical equipment, and medical devices, while 420 stainless steel is typically used to manufacture products that require high strength and hardness such as knives, bearings, and valves.

Although 420 stainless steel has high corrosion resistance, it is not incapable of rusting. Rusting may occur if 420 stainless steel is exposed to moisture, high temperatures, high oxidation or salinity for a long period of time.

In addition, the form of rusting of 420 stainless steel is different from other stainless steels, mainly because of its low chromium content, and pitting or halo-like rusting may occur. Therefore, when using 420 stainless steel products, care should be taken to avoid prolonged exposure to wet or corrosive environments in order to prolong its service life.

To minimize the risk of rusting of 420 stainless steel, surface treatment such as electroplating, polishing and painting can be applied to it. It is also very important to maintain and clean it regularly.