431 Stainless Steel Sheets and Plates Supplier

Do you have any questions about our products or are you looking for a professional 431 stainless steel sheets supplier?

Specifications: 431 Stainless Steel, Grade 431, SS 431, SUS 431, AISI 431(1.4057/BS 431S29)M, X17CrNi16-2, Alloy 431, UNS S43100, Stainless Steel 431, UNE F.3427, SAE 431, SS 2321, AMS 5682

Features: High strength and excellent corrosion resistance, ideal for marine and high-stress applications.

Thickness:0.05mm – 200mm; Width: 600mm – 2000mm; Length: 500mm-12000mm

Standard: ASTM, JIS, EN, GB

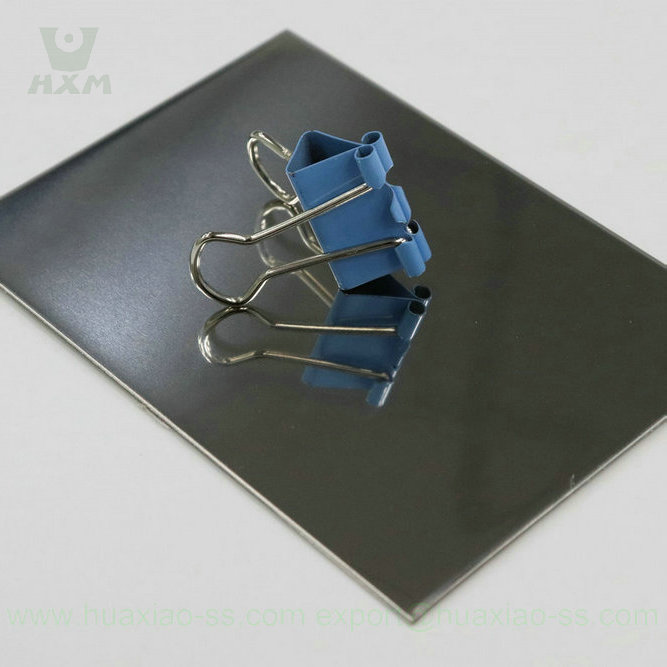

Finish: 2B, 2D, Black, NO.1, Anneal pickling

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Factory Price 431 stainless steel sheets Now

431 Stainless Steel Sheets& Plates Data Sheet

Chemical Composition of ASTM 431 Stainless Steel

| Element | C% | Si% | Mn% | P% | S% | Cr% | Ni% |

|---|---|---|---|---|---|---|---|

| Content | 0.12-0.20 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.030 | 15-17 | 1.25-2.50 |

Mechanical Property of 431 Stainless Steel in Different Standard

| 431 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.7 | 1425-1510 | 24.9 | 10.4 |

| JIS | 7.7 | 1370-1420 | 26 | 10.4 |

| EN | 7.7 | 1370-1420 | 26 | 10.4 |

| GB | 7.7 | 1370-1420 | 26 | 10.4 |

Physical Property of 431 Stainless Steel in Different Standard

| 431 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.7 | 1425-1510 | 24.9 | 10.4 |

| JIS | 7.7 | 1370-1420 | 26 | 10.4 |

| EN | 7.7 | 1370-1420 | 26 | 10.4 |

| GB | 7.7 | 1370-1420 | 26 | 10.4 |

Stainless Steel 431 is available in Strip, Rod, Bars (Round), Wire. For all stock availability contact our Sales Team.

Features of 431 Stainless Steel Sheets& Plates

- Excellent corrosion resistance: Stainless steel 431 sheets resist corrosion effectively in dry air and acidic environments.

- Good wear resistance: High hardness makes 431 stainless steel ideal for components under heavy load and pressure.

- Good machinability: 431 stainless steel is easy to process and offers excellent cutting performance.

- High thermal stability: 431 stainless steel maintains stability under high temperatures and pressures.

- High magnetism: 431 stainless steel is suitable for applications requiring strong magnetic properties.

Weldability of 431 Stainless Steel Sheets& Plates

Grade 431 stainless steel sheets (AISI 431 1.4057/BS 431S29, X17CrNi16-2, UNS S43100, UNE F.3427, SAE 431, SS 2321, AMS 5682) can be welded using specific methods, but certain guidelines must be followed. It is crucial to avoid using hydrogen or nitrogen-rich gases during the welding process. When filler materials are required, 1.4430 (AISI AWS316L) or 1.4370 are recommended, particularly for welds not needing high strength. Preheating can be skipped when using these filler materials; otherwise, the material needs to be heated between 100°C and 300°C before welding. During the process, the temperature should not drop below 200°C. If no further treatment is applied after welding, it’s important to be aware that the mechanical properties of the weld seam may differ significantly from the base material.

Application of 431 Stainless Steel Sheets& Plates

- Automotive Manufacturing Sector: 431 stainless steel sheets(431/1.4057) play a crucial role in automotive manufacturing. Due to their high strength and excellent corrosion resistance, they are often used in the production of automotive axles, bolts, fasteners, and other components to ensure the stability and durability of vehicle structures.

- Chemical Engineering Equipment: 431 stainless steel sheets find extensive applications in the chemical engineering industry. Their excellent corrosion resistance makes them ideal materials for manufacturing chemical engineering equipment such as storage tanks, reactors, pipelines, and valves, capable of withstanding corrosion from various chemical substances.

- Mechanical Manufacturing: Due to its good machinability and wear resistance, SS 431 Sheets are commonly used in the manufacturing of mechanical components such as bearings, gears, etc., ensuring the efficient operation and longevity of mechanical equipment.

- Construction Sector: In the construction sector, stainless steel 431 sheets are used for making decorative materials, railings, doors, windows, etc., due to their corrosion resistance and aesthetic appeal. Their robust and durable characteristics make buildings safer and more durable.

Stainless Steel Sheet Supplier ——HUAXIAO

Thank you for your interest in our 431 stainless steel sheets and plates. We believe that this information will provide valuable reference for your future work and life. If you are looking for a professional and reliable stainless steel supplier, then Huaxiao Metal will be your trusted partner.

As a company engaged in stainless steel export trade for over 15 years, Huaxiao Stainless Steel is headquartered in bustling Shanghai, China, and has rich industry experience and profound market resources. We are committed to providing customers with the highest quality stainless steel products, including various models and specifications of 431 stainless steel sheets, to meet the diverse needs of different customers.

Our sales and shipping departments have rich experience and professional knowledge, and can provide you with comprehensive pre-sales and after-sales services. Whatever questions or requirements you have, we will respond promptly and accurately, ensuring a smooth and pleasant purchasing process for you.

Our Competitive Stainless Steel Products

We will answer your email in 24 hours!

FAQ

Stainless 431 and 316 are two different types of stainless steel, with different compositions and properties.

431 stainless steel sheets is a martensitic stainless steel containing chromium, nickel, and molybdenum. It is characterized by its high strength, toughness, and corrosion resistance, especially in acidic environments. It is often used in applications that require high strength and corrosion resistance, such as pumps, valves, and shafts.

316 stainless steel sheets, on the other hand, is an austenitic stainless steel containing chromium, nickel, and molybdenum. It is characterized by its high corrosion resistance, especially in chloride environments, and excellent formability and weldability. It is commonly used in applications that require good corrosion resistance, such as marine equipment, chemical processing equipment, and medical devices.

In summary, stainless 431 is a high-strength, martensitic stainless steel with good corrosion resistance, while stainless 316 is an austenitic stainless steel with excellent corrosion resistance and good formability and weldability. The choice between these two types of stainless steel depends on the specific application and the desired properties.

There are several key differences between 431 stainless steel and 304 stainless steel, including the following:

- Chemical Composition: 431 stainless steel contains higher levels of chromium (Cr) and nickel (Ni), while 304 stainless steel contains higher levels of chromium and molybdenum (Mo)

- Hardness: Since 431 stainless steel contains higher chromium content, it has higher hardness and strength, while 304 stainless steel is softer

- Corrosion Resistance: 431 stainless steel has better corrosion resistance than 304 stainless steel, especially in high-temperature environments

- Magnetism: 431 stainless steel is a magnetic stainless steel, while 304 stainless steel is a non-magnetic stainless steel.

Therefore, when choosing stainless steel materials, you need to choose the right material according to the specific use environment and requirements. If you need high strength and corrosion resistance, you can choose 431 stainless steel; if you need better processability and decorative properties, you can choose 304 stainless steel.

431 stainless steel plate is a hard stainless steel material with relatively high machining difficulty, but it can still be machined due to its good malleability and machinability. Proper tools and processing parameters, such as proper cutting speed and feed rate, as well as the use of cutting tools with higher hardness and wear resistance, are required to improve processing efficiency and reduce costs during machining. In addition, the weldability of 431 stainless steel plate is also better, but care needs to be taken to select the appropriate welding material and welding process to avoid problems such as hydrogen cracking.

The service life of 431 stainless steel sheet depends on the specific conditions and environment in which it is used, such as working temperature, humidity, chemical exposure, degree of wear and tear, etc. In general, if used in the proper environment and maintained, the service life of 431 stainless steel sheet can be decades or more.

To extend the service life of 431 stainless steel plates, the following measures can be taken:

- Correct Use and Maintenance: avoid prolonged exposure to moisture, high temperature, or corrosive environment, and avoid heavy collisions, friction, and other external damage.

- Regular Cleaning and Maintenance: regularly clean the surface stains, and prevent the accumulation of dust and dirt on the surface, affecting the aesthetic and corrosive properties. In particular, avoid cleaning with chemicals containing chlorine to avoid corrosion of the surface.

- Use Appropriate Accessory Equipment and Tools: such as cutting knives, drills, etc., should be selected with appropriate types and specifications to avoid excessive wear and damage to the tool and workpiece surfaces.

- Proper Storage and Transportation: Avoid contact with other metal materials when storing to prevent oxidation and corrosion; avoid violent collision and vibration when transporting to avoid surface damage.

- Regular Inspection: Conduct regular inspections and maintenance to find and solve problems in time to avoid the aggravation of damage.