Seamless 2205 Stainless Steel Pipe Supplier

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

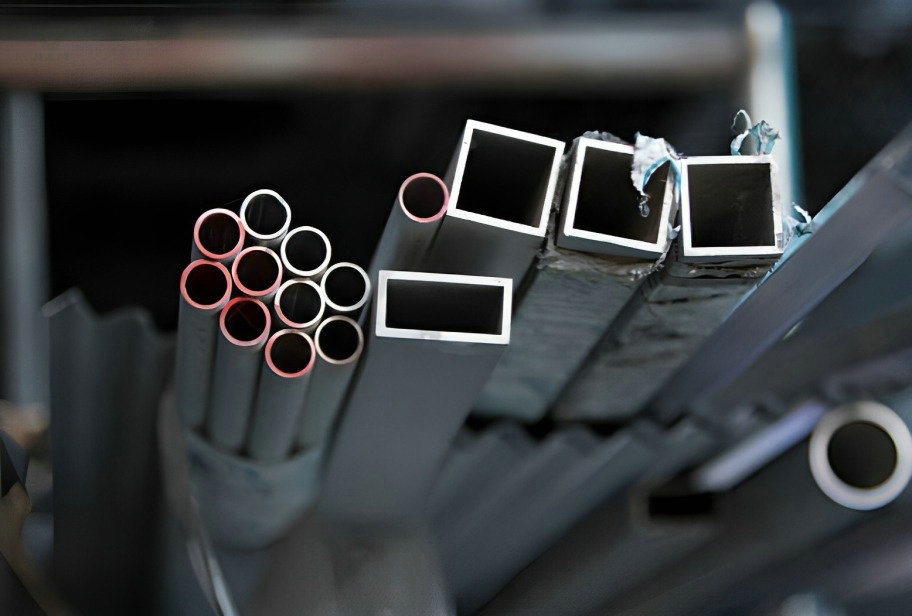

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 2205 Stainless Steel Pipe

Seamless 2205 stainless steel pipes, a duplex (austenitic-ferritic) stainless steel, exhibit exceptional characteristics. They are highly corrosion-resistant, particularly in environments containing chlorides and hydrogen sulfide. Known for their wear resistance and high mechanical strength, these pipes offer superior physical properties that contribute to efficient design. They boast excellent weldability, making them versatile for various applications.

Seamless 2205 stainless steel pipes find widespread use across industries. They are ideal for oil and flowline production, especially in acidic well environments, and are indispensable in refineries and chloride-containing process solutions. These pipes excel in heat exchangers where chloride or brackish water serves as the cooling medium. Moreover, they handle dilute sulfuric acid solutions and organic acids like acetic acid effectively. With its high strength, SAF™ 2205 is a compelling alternative to austenitic steel in structures under heavy loads, offering cost-efficiency through reduced equipment lifecycle expenses.

specification Of Seamless 2205 Stainless Steel Pipe

Chemical Components Of Seamless 2205 Stainless Steel Pipe

| 2205 | C% | Mn% | Si% | Cr% | Ni% | Mo% | N% | S% | P% |

| ASTM | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

| EN | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

| JIS | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 21-23 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 | ≤ 0.03 | ≤ 0.04 |

| GB | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

physical property Of Seamless 2205 Stainless Steel Pipe

| Standards | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.805 | 1420-1465 | 19.7 at 100 ℃ | 13.7 at 20-100°C |

| JIS | 7.805 | 1400-1460 | 19.0 at 100°C | 13.0 at 20-100°C |

| EN | 7.805 | 1400-1450 | 19.0 at 100°C | 13.0 at 20-100°C |

| GB | 7.805 | 1398-1440 | 19.0 at 100°C | 13.0 at 20-100°C |

mechanical property Of Seamless 2205 Stainless Steel Pipe

| Standards | T.S.(MPa) | Y.S.(MPa) | EL.(%) | HB |

| ASTM | ≥ 655 | ≥ 450 | ≥ 25 | ≤ 290 |

| JIS | ≥ 620 | ≥ 450 | ≥ 25 | ≤ 290 |

| EN | 650-880 | ≥ 450 | ≥ 25 | ≤ 310 |

| GB | ≥ 620 | ≥ 450 | ≥ 25 | ≤ 290 |

characteristics Of Seamless 2205 Stainless Steel Pipe

Seamless 2205 stainless steel pipes are renowned for their outstanding corrosion resistance. This characteristic is particularly advantageous in environments containing chlorides and hydrogen sulfide, where many other materials would be susceptible to corrosion and stress corrosion cracking. The key features of the corrosion resistance in these pipes include:

Chloride Resistance: SAF™ 2205 stainless steel demonstrates remarkable resistance to chloride ions. This property is especially vital in applications where exposure to saltwater, marine environments, or chloride-rich substances is prevalent.

Sulfide Resistance: These pipes exhibit excellent resistance to hydrogen sulfide, a corrosive compound commonly found in oil and gas production, petrochemical processes, and wastewater treatment facilities.

Pitting and Crevice Corrosion Resistance: Seamless 2205 stainless steel pipes also provide resistance against pitting and crevice corrosion, which can occur in aggressive environments. This resistance ensures the longevity and reliability of the pipes in various applications.

Acid Resistance: The material’s resistance to acidic conditions, such as those found in chemical processing, enhances its durability and suitability for critical industrial processes.

Long-Term Durability: Due to its superior corrosion resistance, SAF™ 2205 pipes have an extended service life, reducing maintenance and replacement costs in a wide range of industries.

Overall, the exceptional corrosion resistance of seamless 2205 stainless steel pipes makes them a top choice for applications in harsh and corrosive environments, ensuring the integrity and reliability of critical systems and structures.

Wear resistance is another notable characteristic of seamless 2205 stainless steel pipes. These pipes exhibit high resistance to wear and corrosion fatigue, making them well-suited for applications where abrasive substances or mechanical stress may be present.

The wear resistance of seamless 2205 stainless steel pipes ensures their longevity and reliability in demanding environments, such as those found in mining, ore processing, and slurry transport systems. Their ability to withstand abrasive forces contributes to reduced maintenance and replacement costs, making them a cost-effective choice for various industrial applications.

Strength is a prominent feature of seamless 2205 stainless steel pipes. These pipes possess high mechanical strength, approximately twice the yield strength of austenitic stainless steels.

This exceptional strength makes them an ideal choice for applications where structural integrity and load-bearing capacity are essential. Seamless 2205 stainless steel pipes can withstand heavy loads and mechanical stresses, contributing to the safety and reliability of the systems they are incorporated into. Whether used in pipelines, structural components, or other critical applications, their strength ensures long-lasting performance and durability.

Weldability is another notable characteristic of seamless 2205 stainless steel pipes. These pipes exhibit excellent weldability, allowing them to be joined together efficiently through various welding methods.

Their favorable weldability stems from their balanced chemical composition and microstructure, which minimizes the risk of welding-related issues such as cracks or brittleness. Whether using common welding techniques like TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or submerged arc welding, seamless 2205 stainless steel pipes maintain their structural integrity and corrosion resistance after welding.

This feature makes them suitable for a wide range of fabrication processes and applications, providing flexibility in design and assembly while ensuring the pipes maintain their high-performance properties.

application Of Seamless 2205 Stainless Steel Pipe

Oil and Gas Production

In the context of oil and gas production, seamless 2205 stainless steel pipes play a vital role. These pipes are employed in the manufacturing of oil tubing and flowlines used for extracting petroleum and natural gas from wells, including those with acidic conditions. The key advantage lies in their exceptional corrosion resistance, making them ideal for withstanding the harsh and corrosive environments encountered in the oil and gas industry. Additionally, their high mechanical strength ensures the integrity and reliability of these critical components, contributing to efficient and safe operations in the oil and gas sector.

Refineries

Seamless 2205 stainless steel pipes find extensive application in refineries. They are integral components in various refining processes due to their exceptional resistance to corrosion, particularly in environments containing chloride and sulfur compounds. These pipes are employed in the construction of pipelines and equipment used to transport and process crude oil and its derivatives. The high strength and robustness of 2205 stainless steel ensure the reliability and longevity of these critical components in the demanding and corrosive environments of refineries. This, in turn, contributes to the efficiency and safety of refining operations, making seamless 2205 stainless steel pipes an essential choice in the industry.

Heat Exchangers

Seamless 2205 stainless steel pipes play a vital role in heat exchangers within various industries. Their exceptional corrosion resistance and high strength make them ideal for transferring heat between two or more fluids without mixing them. In applications like chemical processing, power generation, and desalination plants, these pipes are used in heat exchangers to efficiently control temperatures and facilitate processes such as cooling or heating. The corrosion-resistant properties of seamless 2205 stainless steel ensure that heat exchangers maintain their integrity and performance over time, even when exposed to aggressive chemicals or high-temperature environments. This reliability is crucial for optimizing energy efficiency and minimizing maintenance costs in heat exchange systems.

Chemical Processing

Seamless 2205 stainless steel pipes find extensive use in chemical processing applications. Their exceptional corrosion resistance and durability make them well-suited for handling various corrosive chemicals and acids, including sulfuric acid, hydrochloric acid, and acetic acid. These pipes are employed in the construction of chemical reactors, pipelines, and storage tanks. Due to their resistance to stress corrosion cracking and pitting, they ensure the safe and reliable transport of chemicals, helping to maintain the integrity of chemical processes and prevent environmental contamination. Additionally, their high strength and weldability contribute to the structural integrity of chemical plants, ensuring long-term operational safety and efficiency.

Structural Applications

Seamless 2205 stainless steel pipes play a vital role in various structural applications. Their exceptional combination of strength, corrosion resistance, and durability makes them a preferred choice for constructing critical structural components in diverse industries. These pipes are commonly used in the construction of bridges, buildings, and offshore platforms, where they provide reliable support and long-lasting performance even in harsh environments. Their resistance to corrosion, including in chloride-rich conditions, ensures the structural integrity of these applications over time. Additionally, the high strength and weldability of seamless 2205 stainless steel pipes make them ideal for load-bearing elements, ensuring the safety and longevity of structural projects.

FAQ

Yes, seamless 2205 stainless steel pipes can typically be customized to meet specific size and thickness requirements. Reputable stainless steel pipe suppliers often offer customization services to ensure that the pipes align precisely with the needs of the project. These suppliers have the capability to manufacture seamless stainless steel pipes in various sizes and thicknesses, allowing customers to select the dimensions that best suit their applications. It’s advisable to consult with reliable stainless steel pipe suppliers to discuss your customization needs and obtain pipes tailored to your project’s specifications.

Yes, seamless 2205 stainless steel pipes are recyclable. Stainless steel, including the 2205 grade, is highly recyclable and retains its properties even after recycling. This makes it an environmentally friendly choice for various applications. Stainless steel pipes can be collected, melted down, and reused to create new stainless steel products, reducing the need for virgin materials and minimizing environmental impact. Reputable stainless steel pipe suppliers often emphasize the sustainability and recyclability of their products, making them an eco-conscious choice for many industries.

The use of duplex stainless steel like 2205 offers several advantages:

Corrosion Resistance: Duplex stainless steel, such as 2205, provides excellent corrosion resistance, making it suitable for environments with high chloride and sulfide concentrations.

Strength: It possesses high mechanical strength, exceeding that of austenitic stainless steels. This strength allows for lighter and more cost-effective designs.

Durability: Duplex stainless steel is known for its durability, with resistance to stress corrosion cracking and fatigue, ensuring a longer service life.

Versatility: It finds applications in various industries, including oil and gas, chemical processing, and marine, thanks to its versatility and ability to withstand extreme conditions.

Cost-Effective: Its combination of properties often leads to cost savings in maintenance and replacements.

Stainless steel pipe suppliers can provide tailored solutions using duplex stainless steel, emphasizing these advantages for specific applications.

Certainly, when welding 2205 stainless steel pipes, there are some key considerations:

Filler Material: Use filler materials specifically designed for duplex stainless steels, often matching the 2205 grade. This ensures the best compatibility and corrosion resistance.

Preheating and Interpass Temperature: Maintain appropriate preheating and interpass temperatures to prevent cracking and promote proper phase balance in the weld.

Welding Method: Common methods include TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, which provide precise control over the welding process.

Post-Weld Heat Treatment: Depending on the application, post-weld heat treatment may be required to enhance properties such as toughness and corrosion resistance.

Welding Techniques: Employ skilled welders who are experienced in working with duplex stainless steels, as their expertise is crucial for achieving quality welds.

Corrosion Protection: After welding, ensure that the welded area is passivated and protected against potential corrosion.

Stainless steel pipe suppliers often offer guidance on welding 2205 stainless steel pipes and can provide the appropriate materials and expertise to ensure successful welding processes.

The manufacturing process for seamless 2205 stainless steel pipes involves several key steps:

Raw Material: High-quality duplex stainless steel billets are sourced, typically matching the 2205 grade composition.

Heating and Piercing: The billets are heated to a suitable temperature and then pierced to create a hollow shell.

Rotary Piercing: The pierced billet is further elongated and reduced in diameter through a rotary piercing process.

Hot Extrusion: The hollow shell is then subjected to hot extrusion, where it is elongated and reduced further to achieve the desired dimensions.

Sizing: The extruded pipe undergoes sizing to achieve precise outer diameter and wall thickness.

Annealing: Heat treatment, such as annealing, is performed to relieve stress and improve mechanical properties.

Straightening: The pipe is straightened to ensure it meets the required straightness specifications.

Cutting and Finishing: The pipe is cut to the desired lengths, and the ends may be beveled for welding preparation. Surface finishing, such as pickling and passivation, is performed to enhance corrosion resistance.

Testing: Various tests, including non-destructive testing (e.g., ultrasonic, eddy current), mechanical testing, and hydrostatic testing, are conducted to ensure the pipe meets quality standards.

Final Inspection: The pipes undergo a final inspection to verify dimensions, mechanical properties, and surface quality.

Packaging: The seamless 2205 stainless steel pipes are then packaged and prepared for shipment.

Stainless steel pipe suppliers follow stringent quality control procedures throughout this manufacturing process to produce seamless 2205 stainless steel pipes that meet industry standards and customer requirements.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China